Description

Megapoxy MC Heavy Duty Maintenance Coating

5 Litre Kit – comprising 4 Litres Part A, 1 Litre Part B

20 Litre Kit – comprising 16 Litres Part A, 4 Litres Part B

.

##NOTE: Minimum 7 Day Lead Time Required for Ordering##

Description

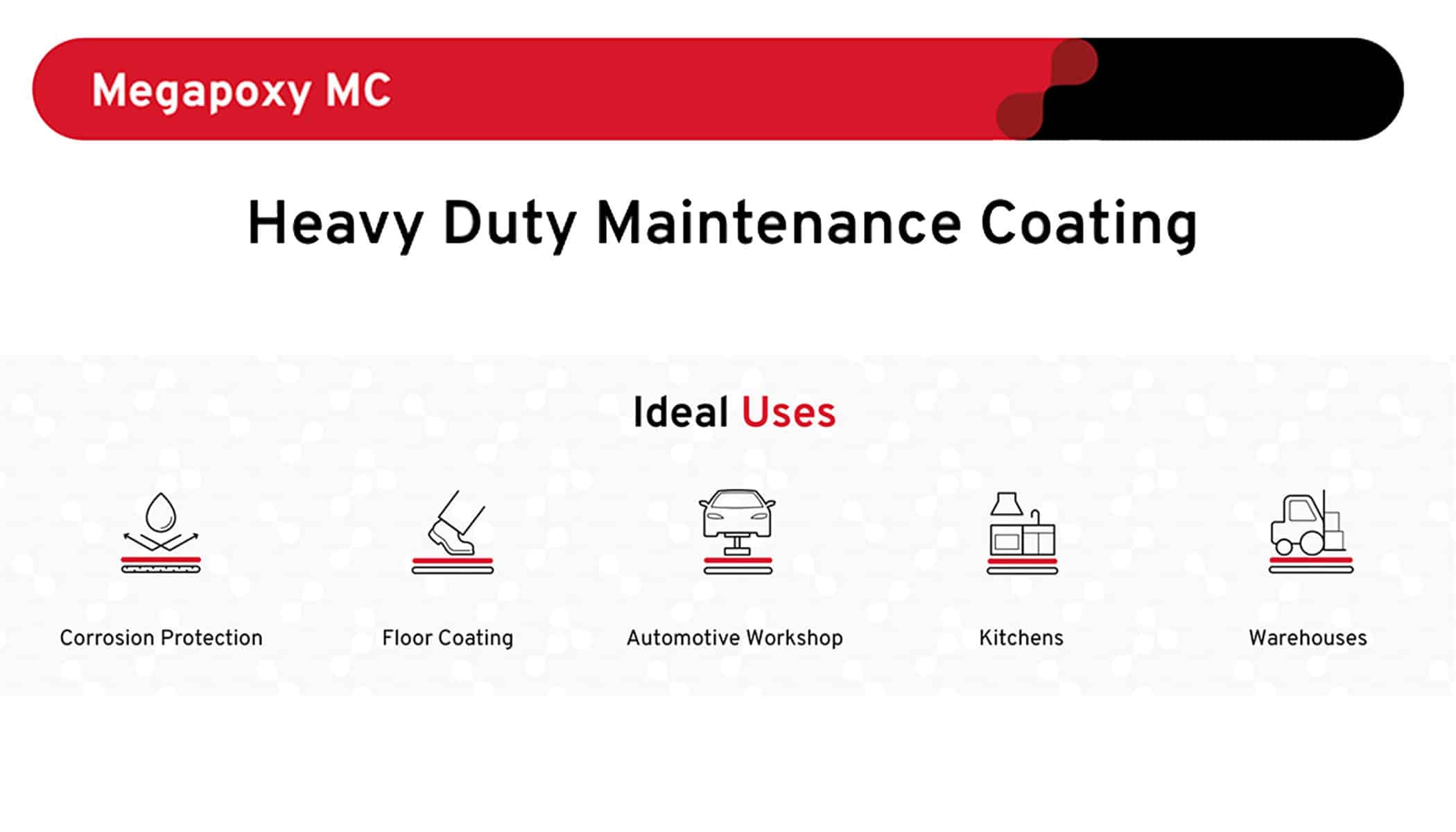

Megapoxy MC Heavy Duty Maintenance Coating is recommended for corrosion protection; floor coating for

automotive workshops; kitchens; warehouses; and many other types of coating applications. Megapoxy MC

Heavy Duty Maintenance Coating is ideal for waterproofing walls and floors; food and beverage production

surfaces; decorative surfaces; and abrasion resistance.

Megapoxy MC Heavy Duty Maintenance Coating is a two component heavy duty, 100% solids, high build, highly

chemical resistant and heavy duty maintenance coating suitable for a variety of commercial and industrial

Megapoxy MC Heavy Duty Maintenance Coating floor, wall and steel protection applications. Megapoxy MC

Heavy Duty Maintenance Coating provides a decorative, hygienic, dust free coating with

heavy abrasion resistance. It is resistant to hydrogen sulphide that may be present in

pipes and plants for the treatment of sewage.

It is recommended that Megapoxy MC Heavy Duty Maintenance Coating is applied in a three coat application

Megapoxy MC Heavy Duty Maintenance Coating when used in particularly aggressive and harsh environments.

This three coat application will give a total cured maintenance coating thickness of 0.4 – 0.5 mm.

Megapoxy MC is volatile organic compounds free (Nil V.O.C.) is suitable for coating and protecting

structures that are in contact with foodstuffs.

Features and Benefits

• VOC Free

• Pre-metered easy to use kit

• Easily mixed by hand or mechanically

• Great Coverage

• Can be applied by brush, roller, squeegee (MC2 only) or airless spray

• Accepts fine aggregates broadcast between coats for non-slip

• Excellent tensile and compressive strengths, superior to concrete

• Excellent chemical resistance

• Gloss finish

Recommended Applications

• Food, Beverage Facilities including Abattoirs

• Chemical Storage Tanks and Bunds

• Protective Coatings for Concrete and Steel

• Car Parks and Ramps including Forklift Areas

• Factory and Warehouse Floors

• Mechanical Workshops

• Sewage Treatment Plants and Pipes

• Plant Rooms and Machine Rooms

How to Use

General

Megapoxy MC Heavy Duty Maintenance Coating is a low-viscosity, heavy-duty maintenance coating for many types of applications. It is stocked in a range of colours and is available in conveniently pre-packaged 5kg and 20kg

kits with a simple 3:1 mix ratio by volume (4:1 by weight).

It has a 2-hour work time and a 24-hour cure time at 25ºC.

Surface Preparation

Concrete:

Concrete should be free from grease and oil. If necessary, clean with industrial heavy duty degreaser.

When clean, remove surface laitance. This is best done by mechanical abrasion such as scabbling,

grit blasting or grinding. If this is not possible acid etching must be carried out. Mix concentrated

hydrochloric acid with equal volume of water and spread at the rate of 0.5 litre per square meter of

concrete surface. Allow to react for about 10 minutes and wash the area thoroughly and scrub with

a stiff bristled broom to remove loose sand. Allow to dry for 24 hours. For maximum adhesion the

concrete should be surface dry.

Metal Surfaces:

Metals should be grit blasted to AS CK 9.4 – 1964 Class 3 finish. If this is not possible, mechanically

abrade the surface to a clean, bright metal surface. Once this abrasion is complete, degrease the

surface by flooding with an industrial grade degreaser. Wire brushing is not entirely satisfactory and

gives minimal adhesion only.

Coated Surfaces:

It is recommend to remove all coatings prior to bonding, bonding to coated surfaces will give inferior

bond strengths compared to bonding directly to a prepared substrate.

• Concrete:

The surface may be either flame-cleaned, or mechanically treated with a scutching tool, to remove all

traces of paint. Complete the preparation by diamond grinding or scabbling.

• Metals:

Steps should be taken to remove all paint and/or galvanizing. Good quality paint stripper should be

used, followed by grit blasting or grinding to a bright metal finish.

Safety and PPE

Megapoxy MC Heavy Duty Maintenance Coating is VOC-free.

As with all epoxy resins, please wear appropriate PPE, including eyewear gloves and clothing.

Mixing Procedure

Add the entire contents of Part B into the Part A tin, there is enough space to combine both parts in

the Part A container.

Megapoxy MC 5kg kits & 20kg kits

Mix the two parts together thoroughly for a minimum of 3 minutes, by hand or using a mechanical

stirrer on a low speed of 200rpm or lower, making sure to scrape the base and corners of the drum,

after 3 minutes, scrape the side of the drum and mix for a further 2 minutes.

Set a timer do not guess the time.

Megapoxy MC2 5kg kits

Mix the two parts together thoroughly for a minimum of 2 minutes, by hand or using a mechanical

stirrer on a low speed of 200rpm or lower, making sure to scrape the base and corners of the drum,

after 2 minutes, scrape the side of the drum and mix for a further 1 minute.

Set a timer do not guess the time.

It is essential that the correct mixing ratio be used and that the Part A and Part B are thoroughly

mixed together before use. Inaccuracies and poor mixing will result in lower physical properties of

the cured system and, if the error is sufficiently large, the system may not cure satisfactorily and

discolour on ageing.

Application

Megapoxy MC Heavy Duty Maintenance Coating can be applied by brush, roller or airless spray equipment. Cut in the edges with a brush before roller coating. We recommend a three-coat application when used in particularly aggressive or harsh environments.

Fine aggregates can be broadcast between coats. They can be applied before curing, as you roll. These can either be left as is for an aggressive non-slip surface or be re-coated with Megapoxy MC to create a less aggressive non-slip surface.

For bulk mixing, ensure that all your tools, along with the Part A and Part B containers, are ready for mixing, but do not combine them or mix multiple batches at once. Only make your second batch once the first has been applied.

Two thin roller coats will give the best result. Ensure you leave time for the first coat to set (8 hours) before applying the second coat.

It is recommended that Megapoxy LVS – Low Viscosity Sealer is used as a primer on particularly

porous surfaces before the application of Megapoxy MC. Megapoxy LVS can be applied either by

roller, brush or spray equipment at a rate of 8-10m² per litre. Single coat application of Megapoxy LVS

is generally all that is required and thinning is not recommended. Recoat or overcoat approximately

between 8 – 24 hours after application of Megapoxy LVS.

Megapoxy MC Heavy Duty Maintenance Coating can be thinned up to 10% with Megapoxy Thinners to promote

easy working. Add a maximum of 10% Megapoxy Thinners on the first coat, 5% on the second coat and so on.

However, care must be taken to ensure that all thinners have evaporated before applying subsequent coats.

If more than 24 hours elapses between coats, it is necessary to thoroughly abrade the coated surface

to a uniform dull finish using 60 grit abrasive paper.

Non-Slip Surfaces

If you wish to have a non slip surface, broadcast epoxy quality sand, glass beads, carborundum or

silicone oxide over the first freshly applied coat. This can either be left as is for an aggressive non slip

surface, Then re-coat with Megapoxy MC to lock the aggregate in-between coats.

A fine aggregate can also be mixed through the Megapoxy MC.

Once the Megapoxy MC has been thoroughly mixed, the addition of approximately 250gms of

required aggregate size per 5kgs of Megapoxy MC, should give a fairly even coat of non-slip when

using a roller on the surface to be coated. Depending on the grip level required, this can be done in all

coats or just the first one.

Clean-up

To keep mixing implements and working tools clean, use Megapoxy Thinners.

Use disposable rubber gloves to protect hands and maintain proper industrial hygiene.

For further details refer to the Megapoxy MC Safety Data Sheet.

Please Dispose of contents and container in accordance with local, regional, national and international regulations.

Packaging

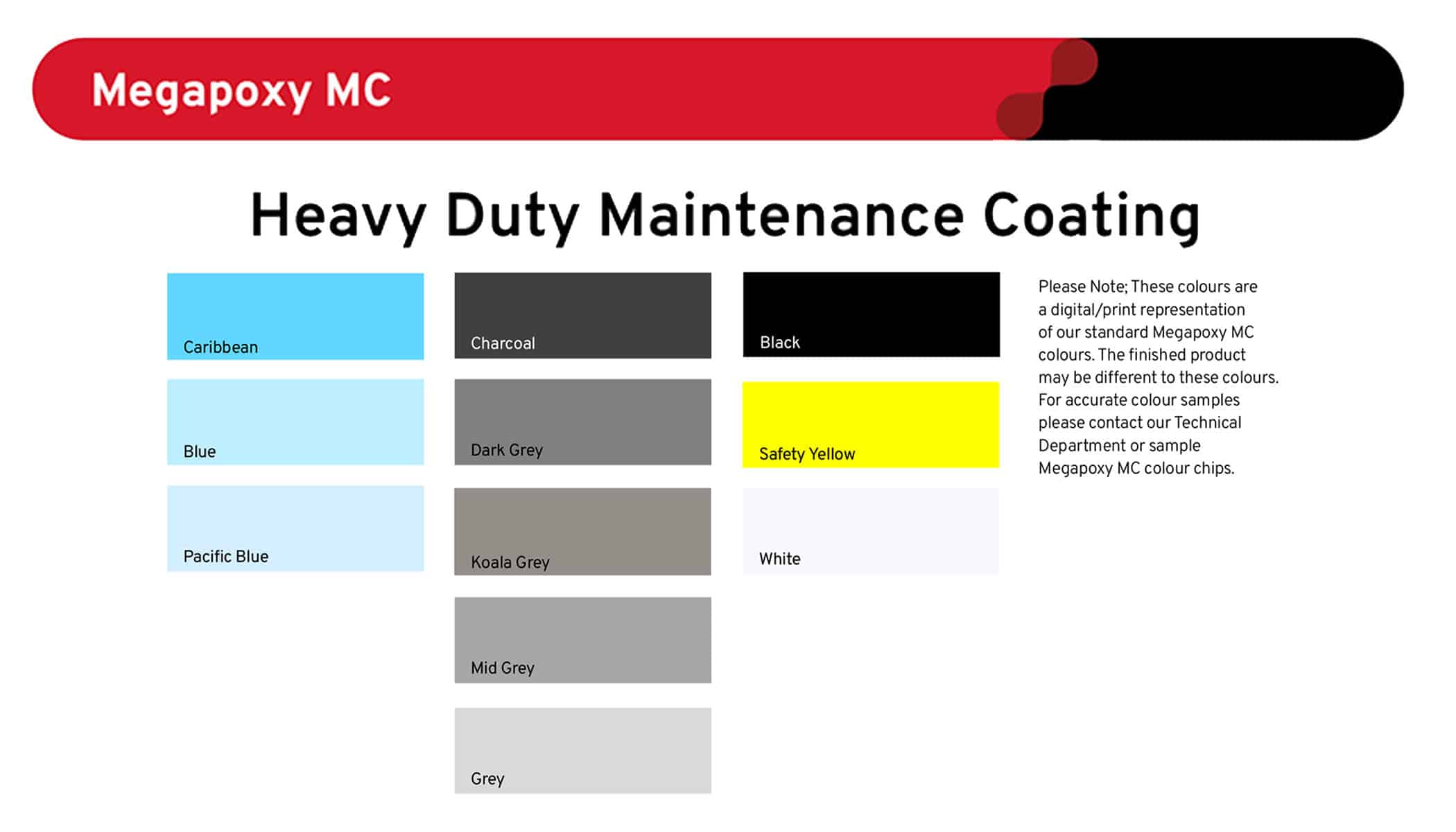

Megapoxy MC & MC2 are available in 5kg kits and 20kg kits.

• 5kg kits: Caribbean Blue, Blue, Pacific Blue, Charcoal, Dark Grey, Mid Grey, Grey, Koala Grey, Safety Yellow, White, Black.

• 20kg kits: Charcoal, Dark Grey, Mid Grey, Grey.

Product should be stored in cool dry store.