Description

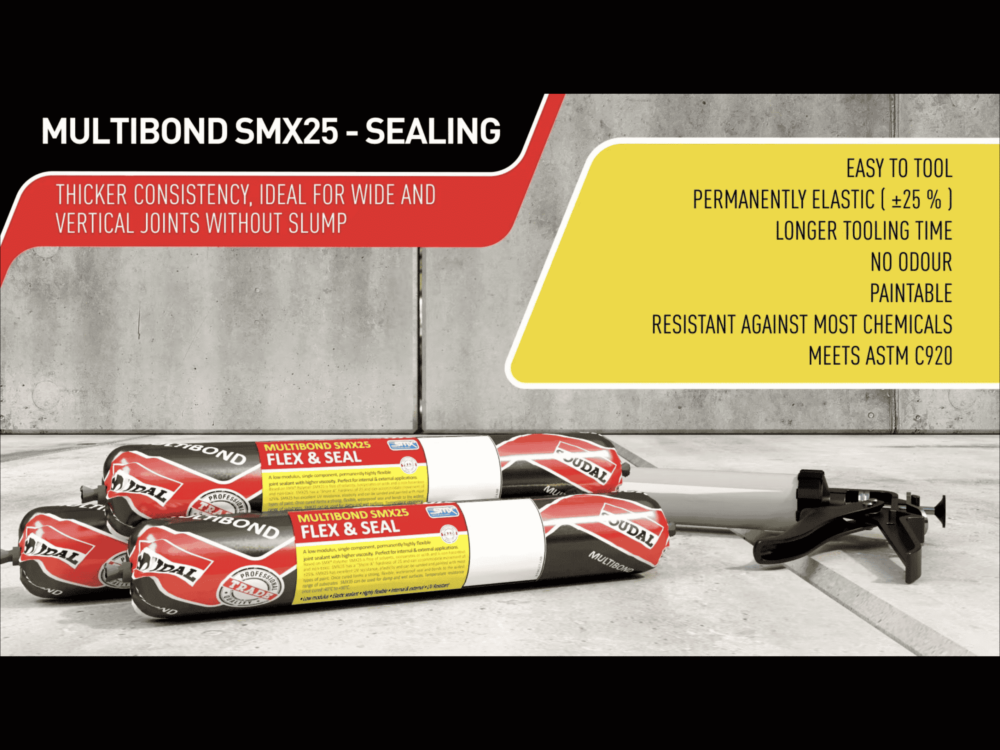

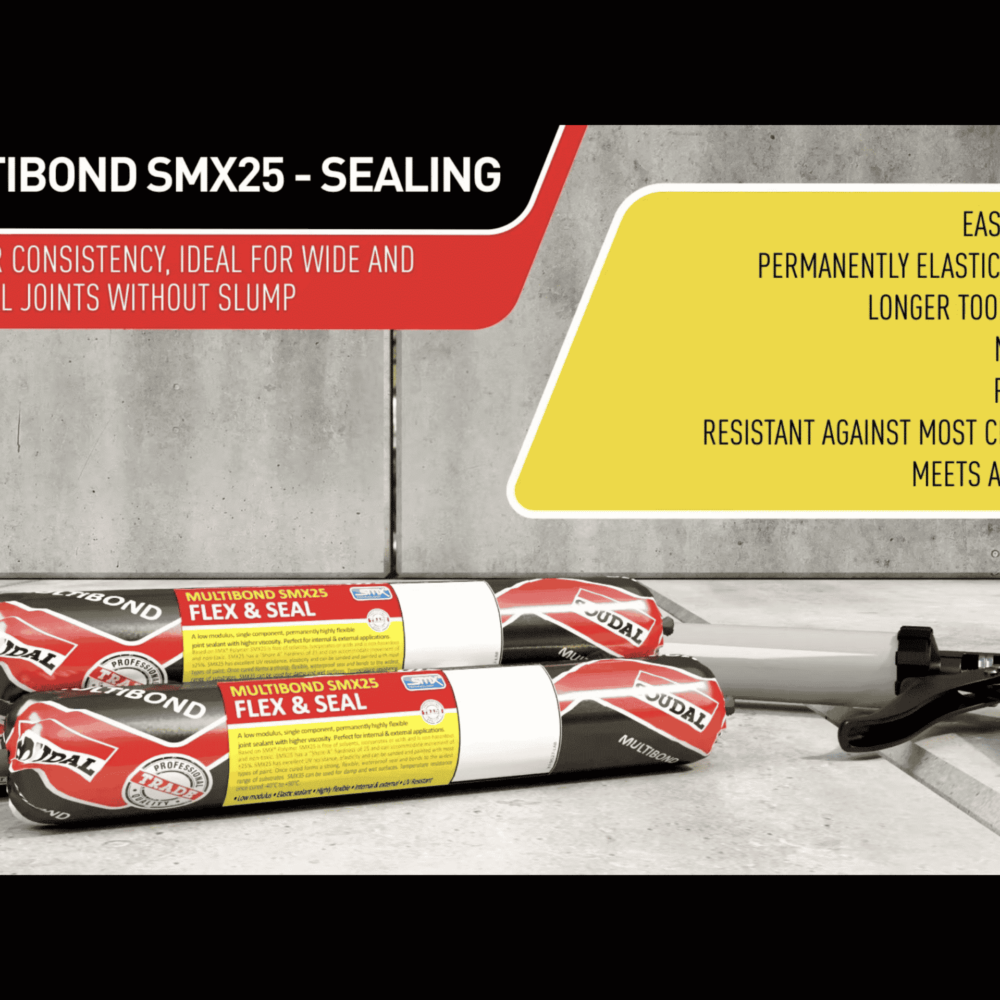

Soudal Multibond SMX25 Flex and Seal

Product description

Soudal Multibond SMX25 Flex and Seal is a high quality, single component, permanently flexible joint sealant. Perfect for internal & external applications. Once cured, forms a strong, flexible, waterproof seal and bonds to the widest range of substrates. Soudal Multibond SMX25 can be used for damp and wet surfaces.

Properties

Soudal Multibond SMX25 Flex and Seal provides the following:

• Good adhesion on most common building materials.

• Easy to tool, extrude (even at low temperatures) and finish in all weather conditions.

• Phthalate-free

• Stays elastic after curing.

• No odour

• No bubble formation within sealant in high temperature and humidity applications.

• Primerless application on many substrates (except where water pressure may occur)

• Can be painted with water based systems

• Good weather and UV resistance

•Solvent, halogen, acid and isocyanate free.

Applications

Soudal Multibond SMX25 Flex and Seal satisfies the following applications:

• Expansion and connection joints in the building industry: sealing of joints in prefabricated buildings, sealing between window and door frames

• Applications where the sealant needs to be overpainted with water based paints and varnishes.

Packaging

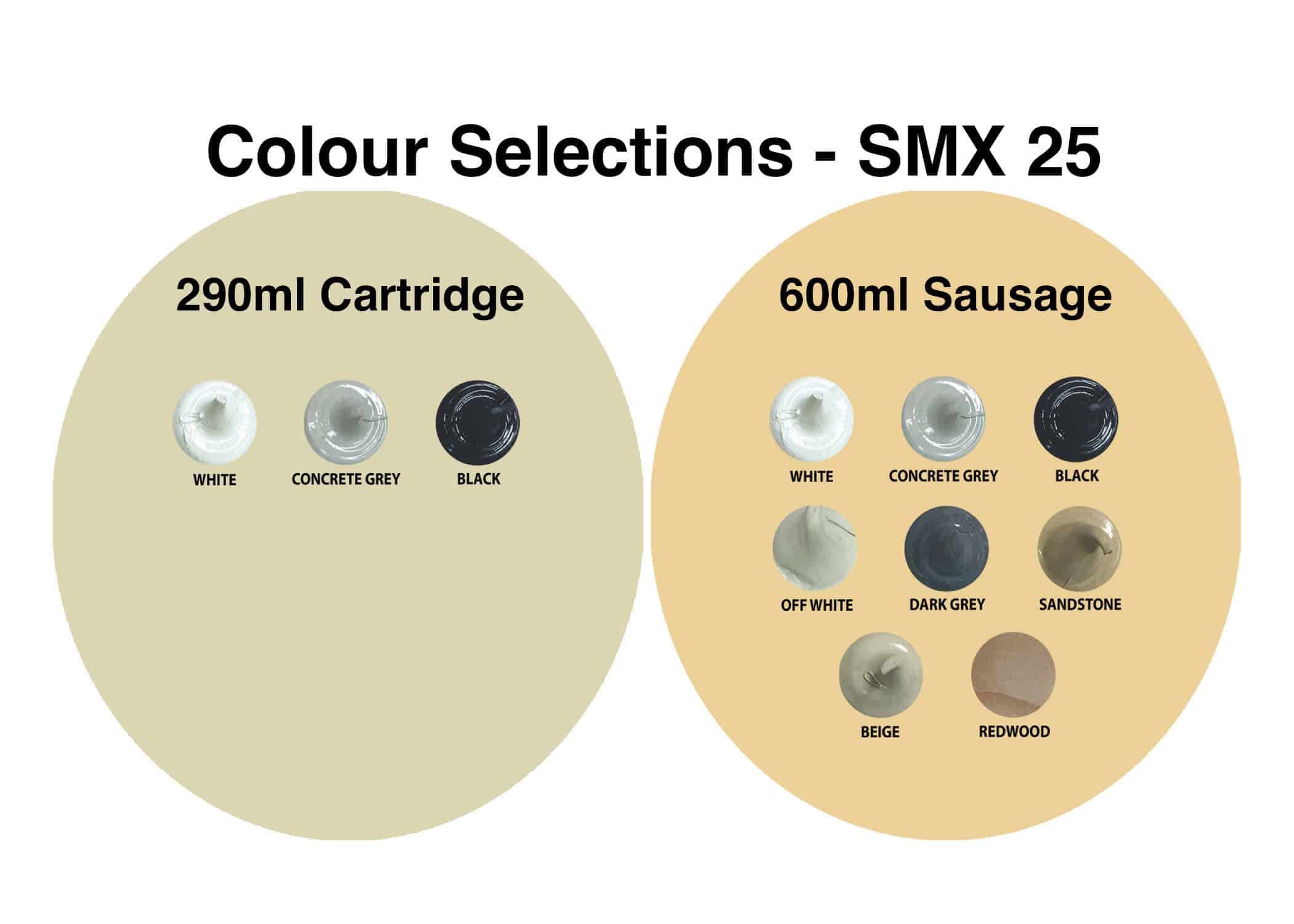

Colour: concrete grey, beige, dark grey, white, old white, black, sandstone, anemone, other colors on request

Packaging: 600 ml sausage, other packaging on request

Shelf life

12 months in unopened packaging in a cool and dry storage place at temperatures between +5°C and +25°C.

Chemical resistance

Good resistance to (salt)water, aliphatic solvents, hydrocarbons, ketones, esters, alcohols, diluted mineral acids and alkalis. Poor resistance to aromatic solvents, concentrated acids and chlorinated hydrocarbons.

Substrates

Substrates: all usual building substrates, aluminium, stone, treated wood, PVC, … Nature: rigid, clean, dry, free of dust and grease.

Surface preparation: Porous surfaces should be primed with Primer 150. Prepare non- porous surfaces with a Soudal activator or cleaner (see Technical Data Sheet).

Not suitable for PE, PP, PTFE (eg Teflon®), bituminous substrates, copper or copper- containing materials such as bronze and brass. We recommend a preliminary adhesion and compatibility test on every surface.

Joint dimensions

Min. width for joints: 5 mm

Max. width for joints: 30 mm

Min. depth for joints: 5 mm

Recommendation sealing jobs: joint width = 2 x joint depth.

Application method

Application method: Soudal Multibond SMX25 Flex and Seal can be used with either manual or pneumatic caulking guns.

Cleaning: Clean with White Spirit or Soudal Surface Cleaner immediately after use (before curing).

Finishing: With a soapy solution or Soudal Finishing Solution before skinning. Repair: With the same material

Health and Safety Recommendations

Take the usual labour hygiene into account.

Consult label and material safety data sheet for more information.

Remarks

• Soudal Multibond SMX25 Flex and Seal may be overpainted with water based paints, however due to the large number of paints and varnishes available we strongly suggest a compatibility test before application.

• The drying time of alkyd resin based paints may increase.

• Soudal Multibond SMX25 Flex and Seal can not be used as a glazing sealant.

• Soudal Multibond SMX25 Flex and Seal is non staining and suitable for sealing on natural stone on condition the joint dimensions and joint movement are respected. Avoid permanent pressure on the sealant.

• When applying, make sure not to spill any sealant on the surface of materials. Taping the surface around the joint can prevent this.

• A total absence of UV can cause a color change of the sealant.

• When using different reactive joint sealants, the first joint sealant must be completely hardened before the next one is applied.

• Not suitable for bonding aquariums.

• Do not use in applications where continuous water immersion is possible.

• Soudal Multibond SMX25 Flex and Seal has a good UV resistance but can discolour under extreme conditions or after very long UV exposure.

• Discoloration due to chemicals, high temperatures, UV-radiation may occur. A change in color does not affect the technical properties of the product.

• Contact with bitumen, tar or other plasticizer releasing materials such as EPDM, neoprene, butyl, etc. is to be avoided since it can give rise to discolouration and loss of adhesion.

Standards and certificates

• U.S.: ASTM C920 type S, grade NS class 25

Environmental clauses

Leed regulation:

Soudal Multibond SMX25 Flex and Seal conforms to the requirements of LEED. Low –Emitting Materials: Adhesives and Sealants. SCAQMD rule 1168.

Complies with USGBC LEED 2009 Credit 4.1: Low-Emitting Materials – Adhesives & Sealants concerning the VOC-content.