Description

Mapei Keracolor GG Large Grain Grout

• 20kg Bag

• Call us for direct invoicing (03 9221 6222) – you save the 3% website Processing Fee

High performance, polymer-modified, cement-based grout for joints from 4 to 15 mm

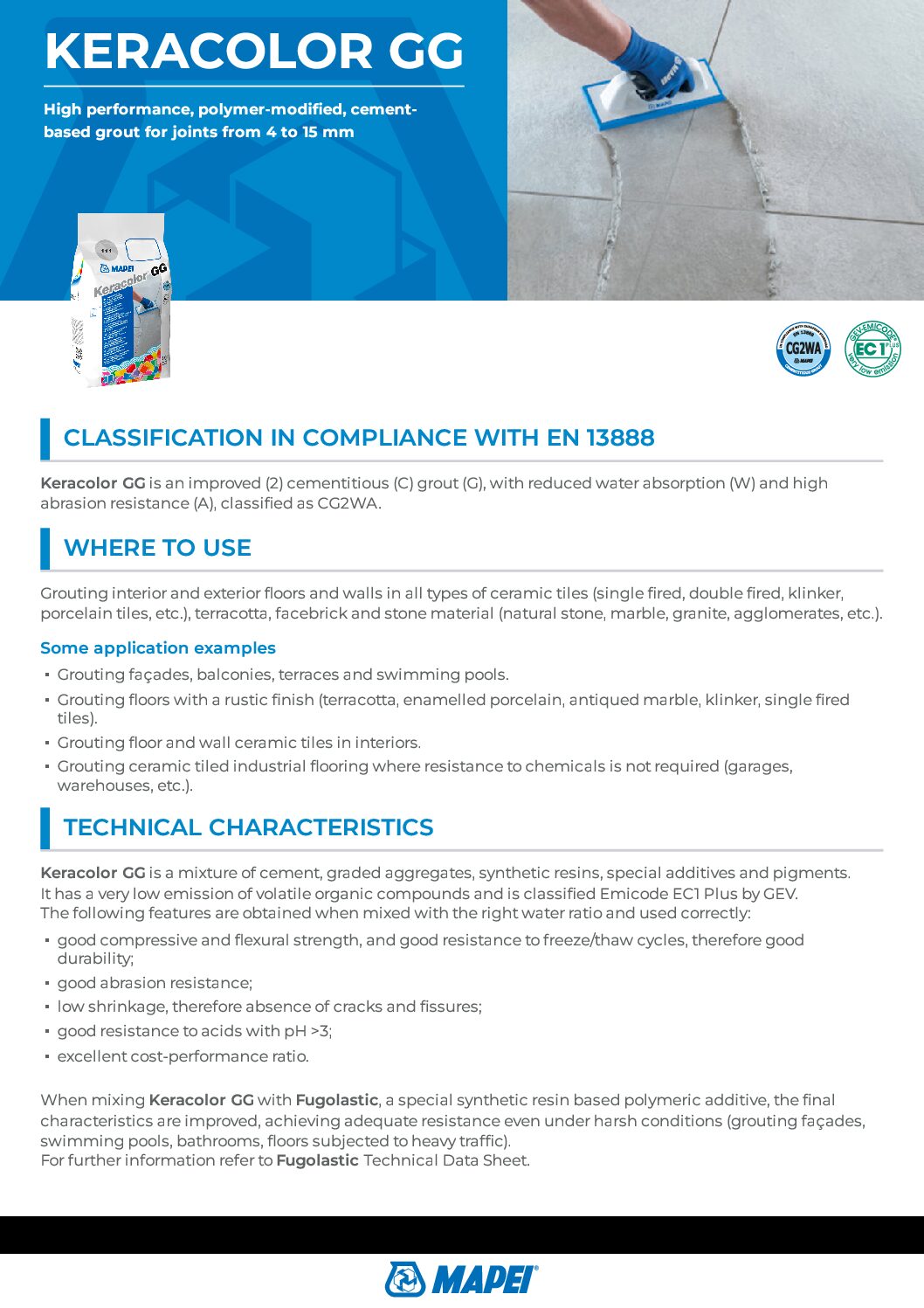

Classification in Compliance with EN13888

Keracolor GG is an improved (2) cementitious (C) grout (G), with reduced water absorption (W) and high abrasion resistance (A), classified as CG2WA.

Where to Use

Grouting interior and exterior floors and walls in all types of ceramic tiles (single fired, double fired, klinker,

porcelain tiles, etc.), terracotta, facebrick and stone material (natural stone, marble, granite, agglomerates, etc.).

Application Examples

- Grouting façades, balconies, terraces and swimming pools.

- Grouting floors with a rustic finish (terracotta, enamelled porcelain, antiqued marble, klinker, single red tiles).

- Grouting floor and wall ceramic tiles in interiors.

- Grouting ceramic tiled industrial flooring where resistance to chemicals is not required (garages, warehouses, etc.).

Technical Characteristics

Keracolor GG is a mixture of cement, graded aggregates, synthetic resins, special additives and pigments.

It has a very low emission of volatile organic compounds and is classified Emicode EC1 Plus by GEV.

The following features are obtained when mixed with the right water ratio and used correctly:

- good compressive and flexural strength, and good resistance to freeze/thaw cycles, therefore good

durability; - good abrasion resistance;

- low shrinkage, therefore absence of cracks and fissures;

- good resistance to acids with pH >3;

- excellent cost-performance ratio.

When mixing Keracolor GG with Fugolastic, a special synthetic resin based polymeric additive, the final

characteristics are improved, achieving adequate resistance even under harsh conditions (grouting façades,

swimming pools, bathrooms, floors subjected to heavy traffic).

For further information refer to Fugolastic Technical Data Sheet

Recommendations

- Do not mix to Keracolor GG with cement or any other products. Never add water to the mixture that has

begun to set. - Do not blend different colours of grout together as there is a risk of colour inconsistency and non-uniform

final shade once the grout has set. - Never mix Keracolor GG with salt or dirty water.

- Use the product in temperatures between +5°C and +35°C.

- The amount of mixing water must be precisely measured. An excess of water could induce the appearance

of a whitish coat over the surface (efflorescence). If mixtures with different mix ratios are prepared, different

colour tones could result. Efflorescence over the surface is due to the formation of calcium carbonate and

could also be caused by moisture residue contained in adhesives, not fully hydrated grouts, in substrates not

adequately dried, or in substrates not adequately protected from rising damp. - After having filled the joints with the mixture, do not broadcast the grouts with Keracolor GG powder to

avoid an uneven colour. - When resistance to acids or hygienic finish is required, use a suitable anti-acid grout (e.g. Kerapoxy).

Expansion joints and distribution joints in floors and walls should never be filled with Keracolor GG, but with

the appropriate flexible MAPEI sealants. - Occasionally the surface of some ceramic tiles or stone materials are rough or contain micro-porosities. It is recommended to make a sample test to verify cleanability and when necessary, apply a protective treatment over the surface, avoiding its penetration into the joints.

Application Procedure

REFER TO TECHNICAL DATA SHEET PDF (See Specifications – Below)

Finishing

When the mixture loses its plasticity and becomes opaque, usually after 10-20 minutes, clean excess

Keracolor GG with a damp hard cellulose sponge (e.g. MAPEI sponge) working diagonally to joints.

Rinse the sponge frequently using two separate buckets of water: one to remove the excess mixture from the sponge

and the other with clean water for rinsing out the sponge.

This can also be carried out with a power float.

To help remove the hardened product from the tiles, use a dampened Scotch-Brite® pad or a disc-type power

Float with special abrasive-felt discs.

If cleaning is carried out too soon (when the mixture is still plastic), the joints may be partially emptied,

therefore more subject to colour variations. On the other hand, if the grout has already hardened, it is

necessary to clean the surface mechanically, which could scratch the surface of the tiles.

When applying Keracolor GG in extremely hot, dry or windy climates, it is recommended to wet the joints after

a few hours.

The wet curing always improves its final performance.

Final cleaning of a powdery haze of Keracolor GG from the surface is carried out with a clean dry cloth.

After the final cleaning, if the surface of the floors or walls is still covered with cementitious residues, an acid

cleaner can be used (e.g. UltraCare Keranet), when the grout is completely cured.

If a product to remove grout residues at the time of application is required, the use of UltraCare Keranet Easy,

suitable to remove excess grout from surfaces immediately after application, is recommended.

For the use of products from the UltraCare range, please refer to the relative Techincal Data Sheets.

Set to Light Foot Traffic

The floors are set to light foot traffic after approximately 24 hours.

Ready for Use

(with hypothetical curing at +23°C and 50% R-H.)

Floors are ready for traffic after 3 days.

Basins and swimming pools can be filled 7 days after grouting.

Cleaning

Clean tools and containers with plenty of water before Keracolor GG hardens.

Packaging

25 kg bags and boxes containing 4×5 alupacks depending on the colour.

Consumption

The consumption of Keracolor GG varies depending on the width of the joints, the size and thickness of the tiles. Please refer to the product calculator to estimate consumption rates at www.mapei.com. Some examples of coverage in kg/m² are shown in the chart.

Storage

Keracolor GG can be stored 12 months (25 kg bags) and 24 months (5 kg bags) in a dry place in its original packaging. Please refer to packaging label.

Safety Instructions

Instructions for the safe use of Mapei products can be found on the latest version of the Safety Data Sheet, available from the Mapei website at www.mapei.com.au

PRODUCT FOR PROFESSIONAL USE