Description

1200 x 900 HPF 5.5mm Underlay

1200mm x 900mm Sheet Size

5.5mm thickness

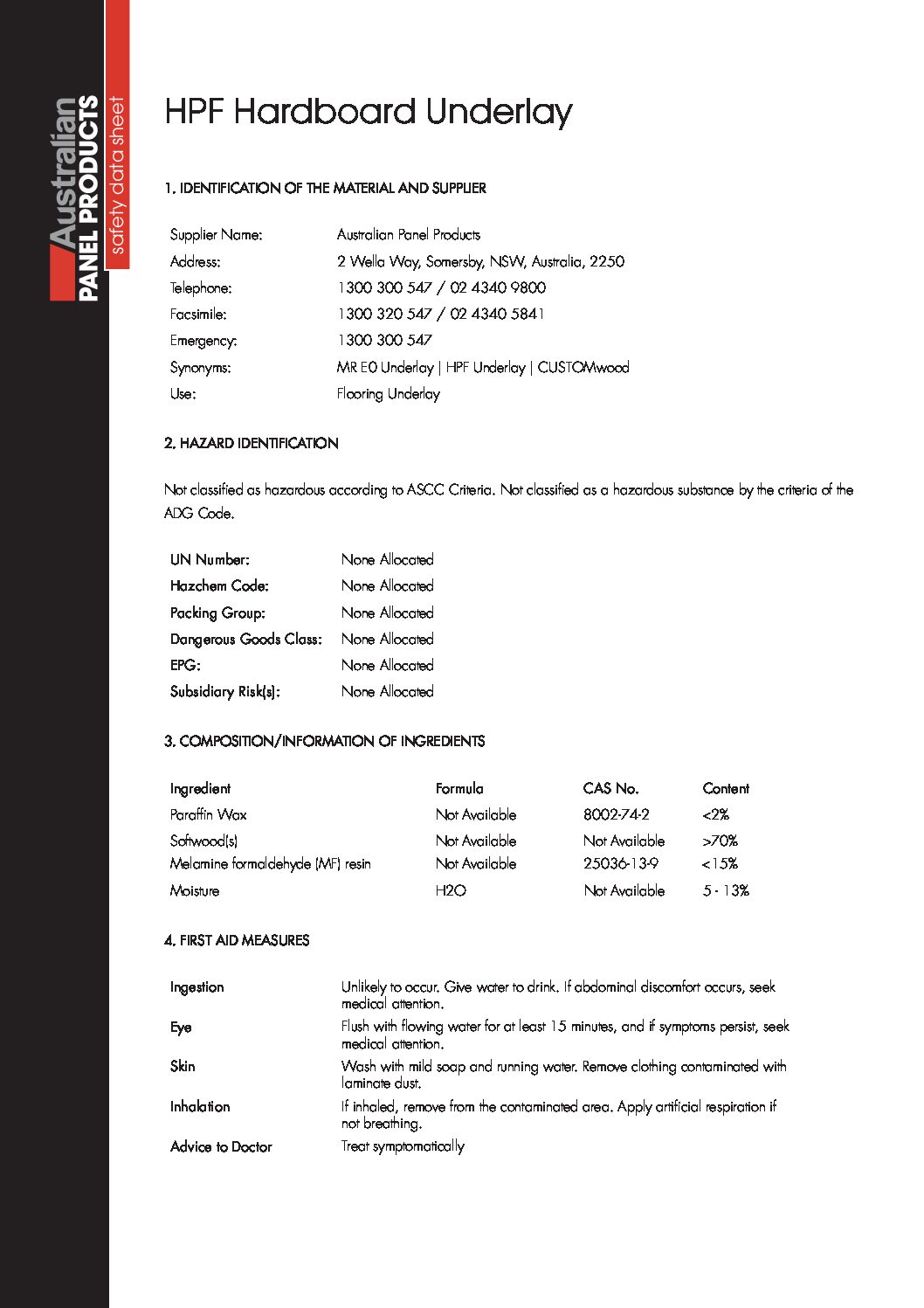

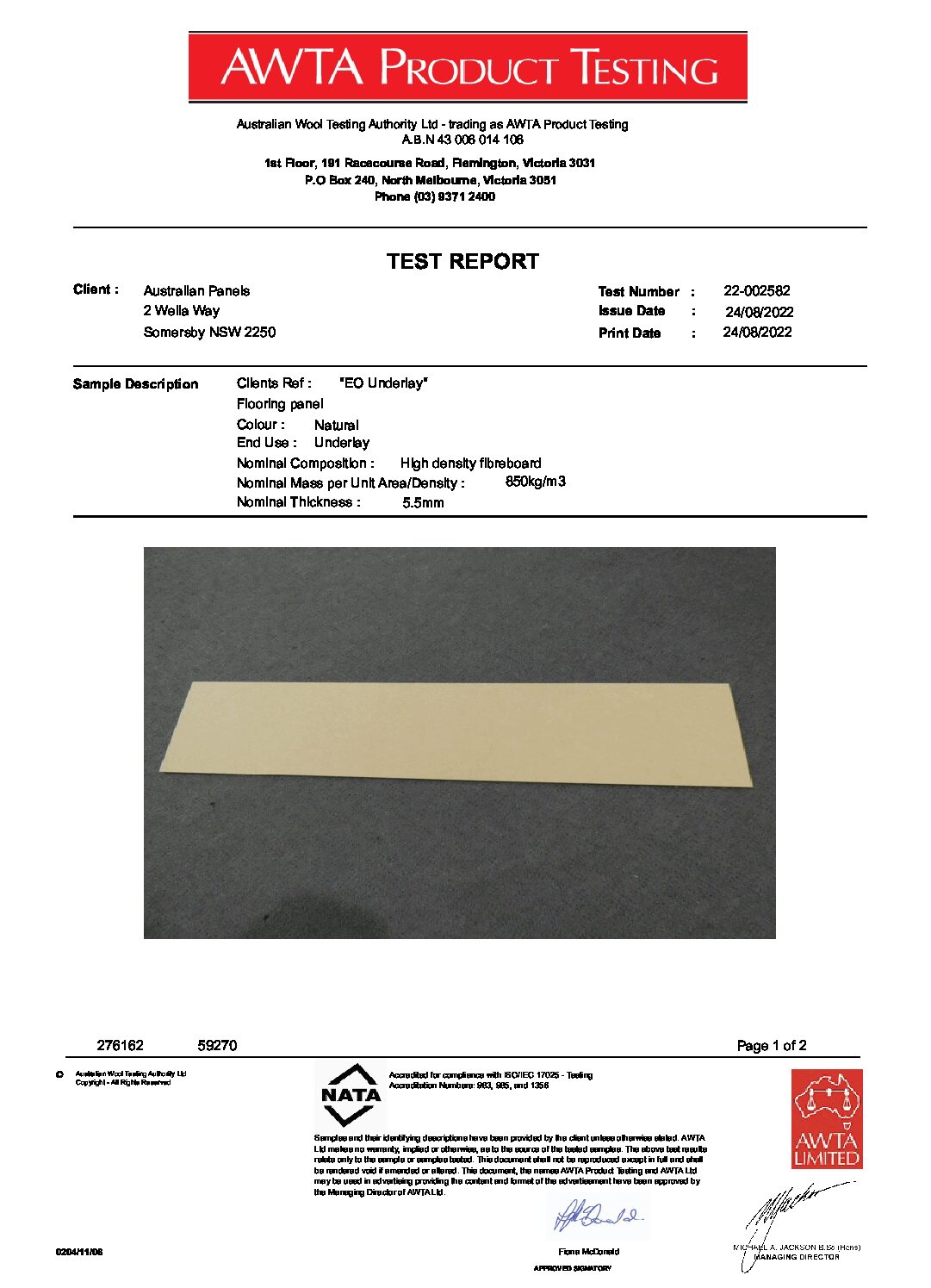

Australian Panel Products High Performance Fibreboard 5.5mm Underlay is an environmentally friendly High Performance Fibreboard underlay manufactured in Australia to E0 standards.

For use over particleboard, strip timber, plywood and concrete flooring 5.5mm HPF Underlay provides a strong flat ultra smooth uniform base for resilient floor coverings.

Features:

- Smart cost saving solution

- E0 and environmentally friendly

- Easy to score and snap with clean snap lines

- Ultra smooth and strong indent resistant surface

- Double sided feature adds strength and versatility

- Minimum face reaction to staples means less sanding and preparation work required

- Complies with Australian Standards AS 1884

Details:

- Thickness: 5.5mm

- Sheet Size: 1200mm x 900mm

- Density: 850kg/m3

- Sheet Area: 1.08m2

- Mass/Unit Area: 4.67kg/m2

- Weight per Sheet: 5.04kg/sheet

- Internal Bond: 1200kPa

- Pallet Quantity: 140 Sheets

- MOR: 40MPa

- MOE: 4000MPa

Size Tolerances:

- Thickness: ±0.15mm

- Length and Width: ±1.5mm

- Squareness (Diagonal Variation): 2.0mm Max

Installation:

Particleboard, Plywood & Timber

Proper site and sub fl oor preparation is crucial to attaining the best performance from your underlay.

Subfloor ventilation; moisture content above and below the sub floor must be checked prior to installation (with correct

timber moisture reader) as per Australian Standards.

Crossflow ventilation shall exist under all timber floors and the area under the floor shall be free from damp. Any signs of dampness or moisture needs to be rectified and the sub floor allowed to dry completely prior to laying underlay. Failure to provide proper ventilation or to correct any dampness or moisture issues can lead to distortion, decaying and movement of the sub floor and underlay or subsequent damage to the floor covering material or adhesive system.

It is ideal that at its lowest point a clearance of 400mm should be provided from the surface of the ground to the underside of the building. Vents should be sized and spaced to provide 7500mm2 opening per metre length of wall. Always consider local regulatory authority clearance requirement as minimum.

• 5.5 HPF Underlay must never be used where moisture content exceeds 14%

• 5.5 HPF Underlay must never be used in exterior applications or areas exposed to water or high humidity

• 5.5 HPF Underlay must also be kept clear of nearby heat sources such as fuel heaters or freestanding fireplaces

A structurally sound uniform sub floor is crucial in attaining the best performance from your underlay.

Structural substrate movement as a result of climatic conditions, faulty or damaged sub floor could adversely affect

the installation and/or performance of underlay.

Any loose impediments, sub floor movement, rough, cupped or warped surfaces must be replaced or rectified to provide a

structurally sound and flat surface prior to the laying of underlay.

NOTE It is up to the contractor to provide a written report to the customer or builder if they believe the sub floor is

unsuitable for any reason which may aff ect the satisfactory execution of the work or impair the durability of the floor

covering or installation systems. Always dry lay the underlay for 24 hours to allow for acclimatisation.

Always use proper adhesive and fixing methods.

Concrete

Always refer to Australian Standards AS1884 when laying over a concrete sub floor.

The concrete substrate must be protected from the entry of moisture by means of a continuous impermeable membrane.

The concrete substrate must be allowed to dry; this is considered satisfactory when the relative humidity does not

exceed 75%.

Always dry lay the underlay for 24 hours to allow for acclimatisation.

Fastener Spacing:

- 10mm in from perimeter of sheet

- 75mm spacing around the perimeter of sheet

- 150mm spacing through body of sheet

- Staples are the recommended method of fixing

- Staples should be driven no more than 0.5mm into the sheet

- Nails should be fi nished absolutely flush with the sheet

(Failure to finish nails flush will result in show through) - The correct number of fixings must be allowed for

Sheet Layout:

- Where possible lay sheets in brick pattern

- Allow 0.4mm gap between sheets

- Allow a perimeter gap of 3mm

Adhesives and Fixing:

Timber, particleboard & plywood sub floor; the use of a flexible adhesive in conjunction with staples MUST be used.

Adhesive type; always use premium grade flexible adhesives.

Always refer to recommendation of relevant adhesive manufacturer.

Concrete; always use premium grade flexible adhesive applied with V3 trowel.

Place underlay into adhesive and roll with 40kg roller, allow for adhesive to cure.

Finishing:

Lightly sand joints and fixing points with a fl at based sanding machine or fixing block to a flush finish.

Disk type sanders are not recommended. Sweep or vacuum to ensure all loose fibre and dust is removed.

Failure to provide a smooth ridge and indentation free underlay will result in unsightly show through or blemishes in the resilient floor coverings.

NOTE AS 1884 Underlay joint show through; where underlay is laid over timber, plywood or particleboard subfloors, the

outline of sheet joins may show through resilient floor covering materials under certain lighting conditions. This show through may also occur as the moisture content of timber changes in response to variations in atmospheric relative humidity conditions.

Storage:

Underlay must not be stored in areas subject to;

• High humidity

• Direct water contact

• Direct sunlight

• Abnormal temperature variation

Fixing type; 22mm resin coated staples are recommended when fixing underlay to particleboard, plywood or solid timber

sub floors (or 3mm longer than existing sub floor).

Supplier Code:

HPF55