Description

MaxWax Wax-Based Corrosion Inhibitor

– 341g Aerosol

– 3.78 Litre Jerry Can

– 18.9 Litre Keg

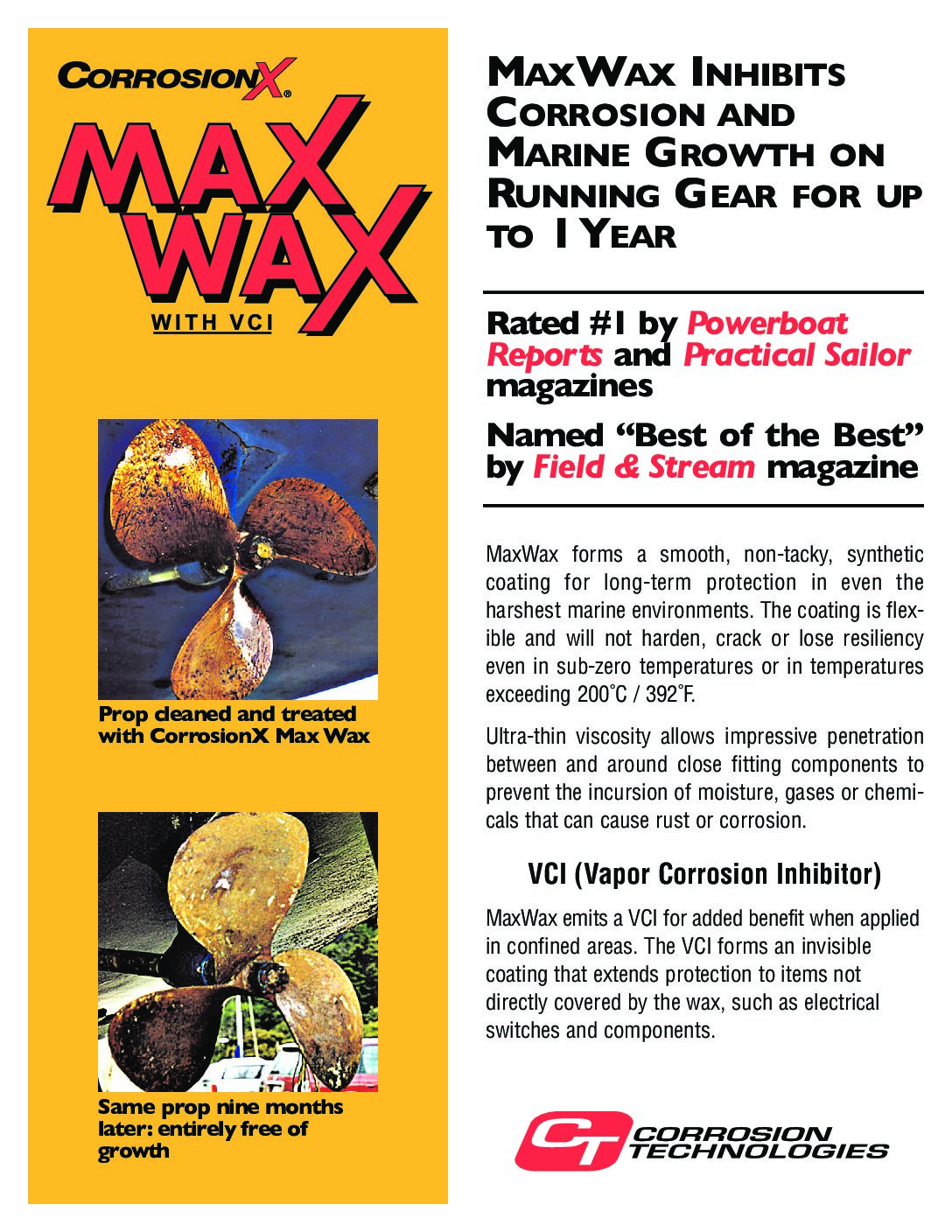

MaxWax provides excellent protection to metal substrates exposed to harsh outdoor conditions. Leaves a firm, waxy film that is easily removed by alkaline cleaners or solvents for quicker results.

MaxWax is a tough, synthetic wax-based, resilient corrosion inhibitor barrier coating that provides long-term protection for metal surfaces. It forms a smooth, even coating for maximum protection even in the harshest environments and underwater.

MaxWax dries faster than other wax-based corrosion inhibitors, and it will not harden, crack or lose resiliency even in sub-zero temperatures It can withstand temperatures exceeding 200°C / 392°F. Its ultra-thin viscosity allows penetration between and around close fitting components to prevent moisture, gasses or chemicals from causing rust or corrosion.

MaxWax is acid resistant. VCI (Vapor Corrosion Inhibitor) Technology MaxWax emits a time release Vapor Corrosion Inhibitor (VCI) for added benefit when applied in confined areas. The VCI forms an invisible coating that protects items not covered by the wax, such as tools in a toolbox, engines in an engine compartment, and electrical switches and components in an electrical box or cabinet.

FEATURES:

• Flexible.

• Excellent outdoor protection.

• Multi-metal protection.

• Excellent UV resistance.

• Moisture displacing.

• Cured film is heat stable up to 392oF (200oC).

• Conforms to MIL-C-16173D (Grades 1 and 2).

• NSN 8030-00-62-6950.

• NATO 6850-66-132-5848.

• NATO 6850-55-132-6099.

APPLICATIONS:

• Pipe coating

• Steel plate

• Machined parts

• Underbody coating

• Wire rope

METALS PROTECTED:

• Carbon Steel

• Stainless Steel

• Copper

• Aluminum

• Cast Iron

APPLICATION:

MaxWax may be applied by bulk dipping or brushing or by spraying. Film thicknesses of at least 2-3 mils (50- 70microns) are recommended for uncovered outdoor storage.

PROTECTION PROPERTIES:

Salt Spray B-117 ASTM Carbon Steel (1010) 2-3 mils DFT (50-75 microns): 900-1500 hour

CLEANUP:

Use solvents or mineral spirits for cleanup of equipment. Solvents, wax strippers, or alkaline cleaners can be used for clean up of overspray.

TYPICAL PROPERTIES

Appearance: Dark brown liquid

Drying to Touch Time: .5 – 3 hours*

Film Type: Firm, wax-like

Non-volatile Content: 60-65%

Shelf Life: 12 months @ 75oF (24oC)

Coverage: 300-330 ft2/gal @ 3 mils (7-8 m2/l @ 75 microns)

Viscosity: 600-5,000 cps

Density: 7.4-7.7 lb/gal (0.89-0.92 kg/l)

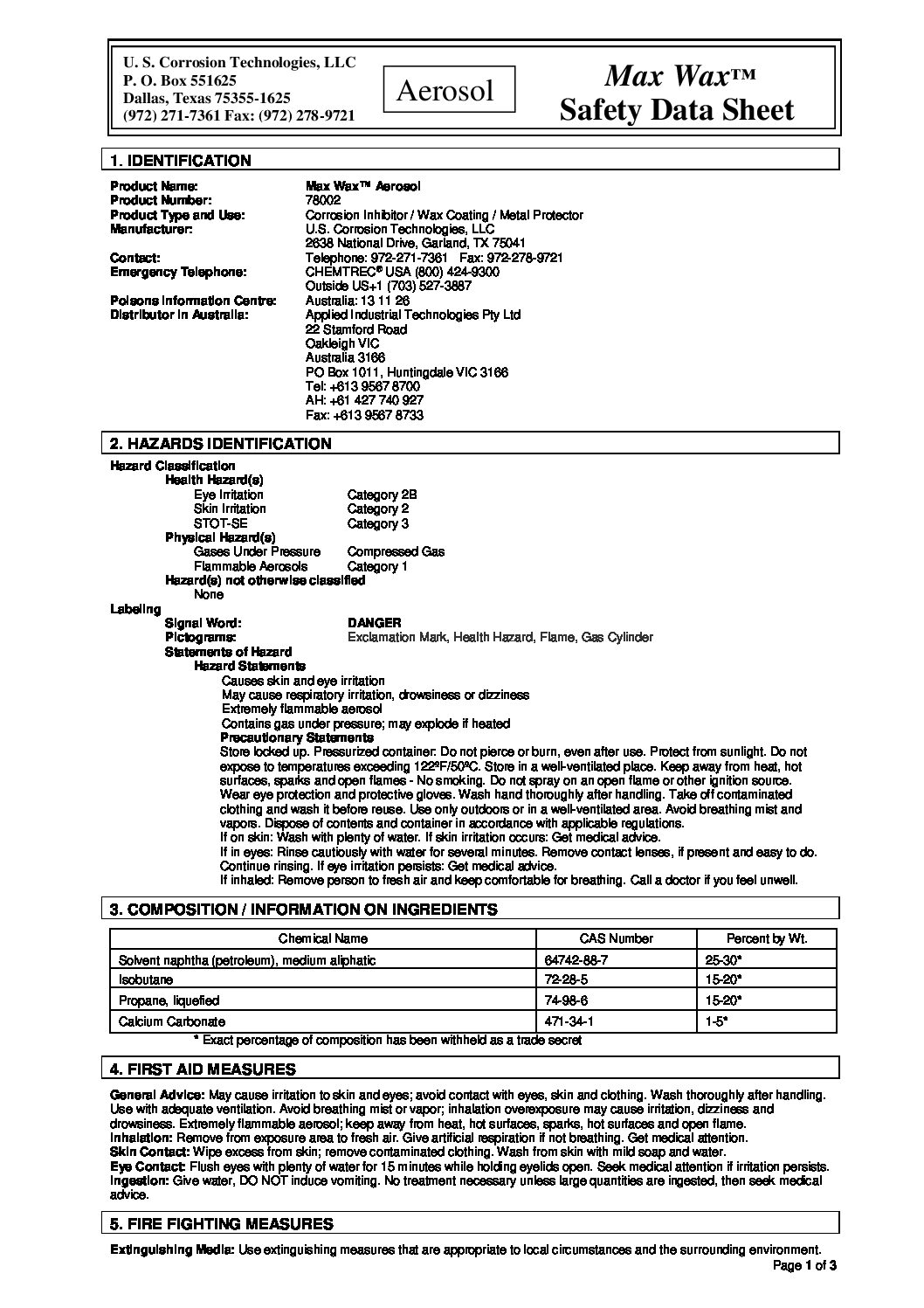

FIRST AID

General Advice: May cause irritation to skin and eyes; avoid contact with eyes, skin and clothing.

Wash thoroughly after handling.

Use with adequate ventilation.

Avoid breathing mist or vapor; inhalation overexposure may cause irritation, dizziness and drowsiness.

Extremely flammable aerosol; keep away from heat, hot surfaces, sparks, hot surfaces and open flame.

Inhalation: Remove from exposure area to fresh air. Give artificial respiration if not breathing. Get medical attention.

Skin Contact: Wipe excess from skin; remove contaminated clothing. Wash from skin with mild soap and water.

Eye Contact: Flush eyes with plenty of water for 15 minutes while holding eyelids open. Seek medical attention if irritation persists.

Ingestion: Give water, DO NOT induce vomiting. No treatment necessary unless large quantities are ingested, then seek medical advice.