Description

Soudal Contractors 701 NS Silicone

General

Soudal Contractors 701 NS Silicone is a high-performing, low modulus, neutral cure sanitary silicone that is virtually odourless and no M.E.K.O. Highly flexible, colourfast and suitable for a wide range of applications that requires a waterproof seal where a maximum protection against mould and mildew is required

Features

Soudal Contractors 701 NS Silicone is:

• Very easy to apply

• Colourfast and UV resistant

• Permanently elastic after curing impervious to mould

Specification

Soudal Contractors 701 NS Silicone provides:

• Very good adhesion on many materials

• Low modulus and Neutral curing MEKO free

Properties

Soudal Contractors 701 NS Silicone is:

•Very easy to apply

• Colourfast and UV resistant

• Permanently elastic after curing

• Impervious to mould

• Very good adhesion on many materials

• Low modulus

• Neutral curing

• MEKO free

Applications

Soudal Contractors 701 NS Silicone can be used for:

• Joints in sanitary rooms (on synthetic baths and tubs) and kitchens.

• All usual building joints with high movement.

• Expansion joints between many different construction materials.

Packaging

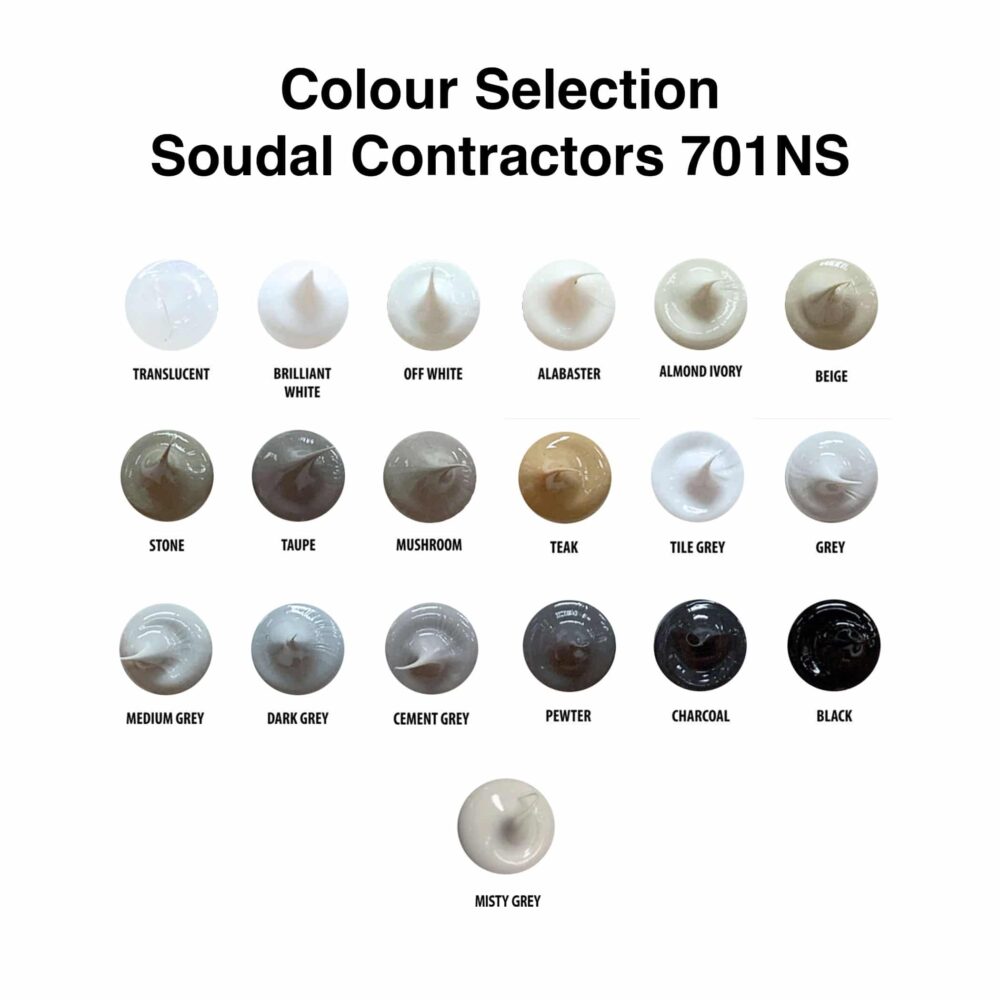

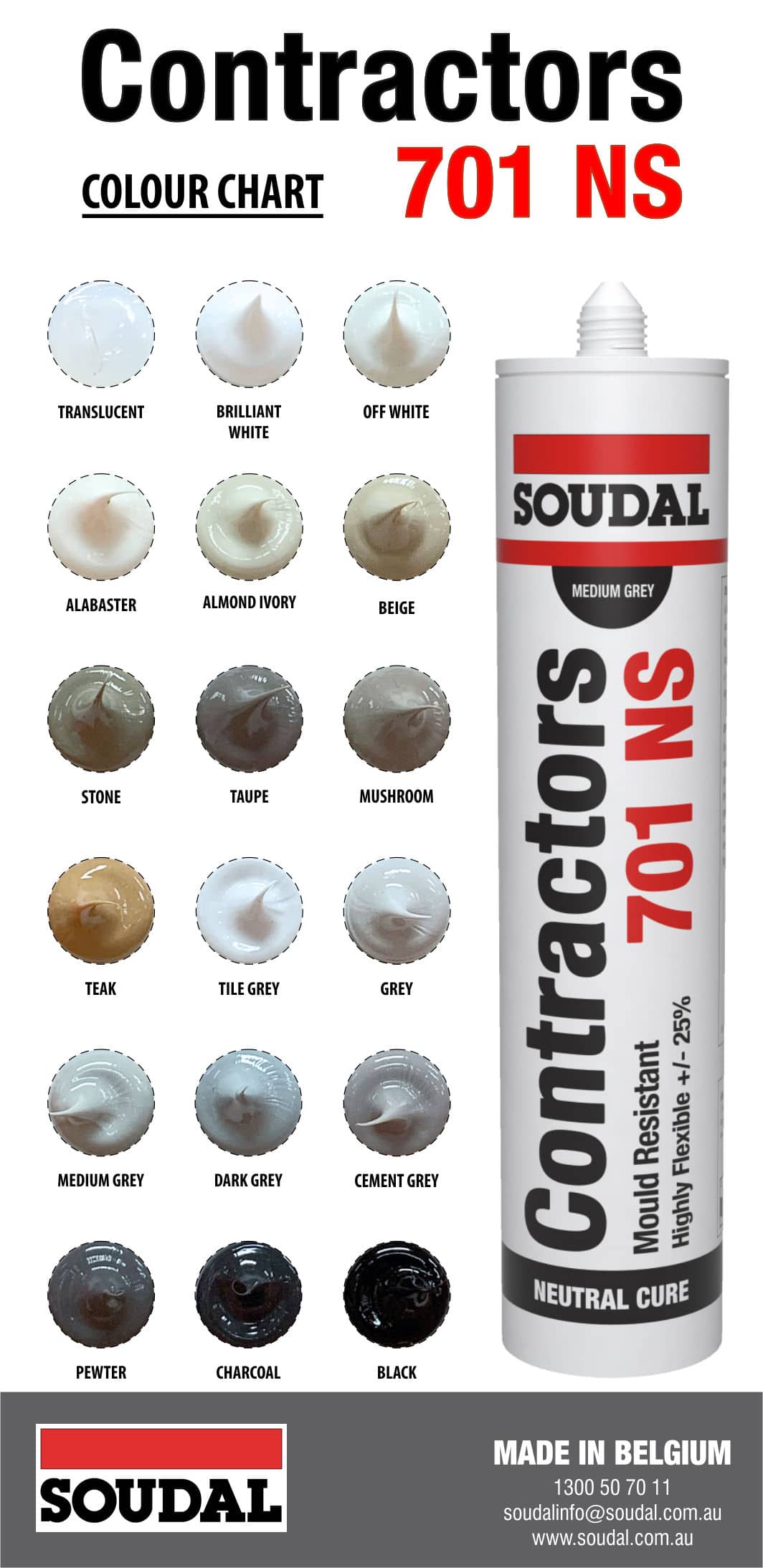

Colour: as selected

Packaging: 300 ml cartridge

Shelf life

The shelf life of Soudal Contractors 701 NS Silicone is 15 months unopened and stored in dry and cool conditions (Between 5 and 25 °C)

Substrates

Substrates: all usual building substrates Nature: rigid, clean, dry, free of dust and grease.

Surface preparation: Porous surfaces should be primed with Primer 150. Prepare non- porous surfaces with a Soudal activator or cleaner (see Technical Data Sheet).

There is no adhesion on PE, PP, PTFE (Teflon®) and bituminous substrates. We recommend a preliminary adhesion test on any substrate. In contact with certain surfaces such as bitumen or copper, discoloration may occur due to reaction with the substrate. On PVC we recommend a preliminary adhesion test. Certain paints and textured coatings on aluminum profiles can influence the adhesion.

Joint dimensions

Min. width for joints: 5 mm

Max. width for joints: 30 mm

Min. depth for joints: 5 mm

Recommendation sealing jobs: joint width = 2 x joint depth. Three-point adhesion should be avoided at all time. Too small joint dimensions can have the effect that the silicone is pulled off because of too large movements.

Application method

Application method: With a manual, pneumatic or accu caulking gun.

Cleaning: Clean with White Spirit or Soudal Surface Cleaner immediately after use (before curing).

Finishing: With a soapy solution or Soudal Finishing Solution before skinning. Repair: With the same material.

Health- and Safety Recommendations

Take the usual labour hygiene into account. Consult label and material safety data sheet for more information.

Remarks regarding Soudal Contractors 701 NS Silicone

•Direct contact with the secondary sealing of insulating glass units (insulation) and the PVB-film of safety glass must be avoided.

• Because of the diversity we recommend to do adhesion tests on aluminum lackers, textured coating and PVC before application.

• In an acid environment or in a dark room, a white sealant can slightly turn yellow. Under the influence of sunlight it will turn back to its initial colour.

• When finished with a finishing solution or soapy solution, make sure that the surfaces are not touched by this solution. This will cause the sealant not to adhere to that surface. Therefore we recommend to only dip the finishing tool in this solution.

• The sanitary formula should not replace regular cleaning of the joint. Excessive contamination, deposits or soap remainigs will stimulate the development of fungi.

• Do not use on polycarbonate. Use Silirub PC instead.

• When using different reactive joint sealants, the first joint sealant must be completely hardened before the next one is applied.

• Contractors 701 NS cannot be used on natural stone.

• Not suitable for bonding aquariums.

• Contact with bitumen, tar or other

plasticizer releasing materials such as EPDM, neoprene, butyl, etc. is to be avoided since it can give rise to discolouration and loss of adhesion.

• Discoloration due to chemicals, high temperatures, UV-radiation may occur. A change in color does not affect the technical properties of the product.

• When applying, make sure that the surface of the materials is not smudged with sealant.

Environmental clauses

Leed regulation:

Soudal Contractors 701 NS Silicone conforms to the requirements of LEED. Low –Emitting Materials: Adhesives and Sealants. SCAQMD rule 1168. Complies with USGBC LEED 2009 Credit 4.1: Low-Emitting Materials – Adhesives & Sealants concerning the VOC-content.