Description

Maxisil N Natural Stone Silicone

GENERAL

Maxisil N Natural Stone Silicone is a non-staining neutral cure silicone designed for expansion joints in natural stone such as marble and granite.

Can be used for interior and exterior areas.

Maxisil N Natural Stone Silicone guarantees that there is no danger of migration of softeners or other components into the edge of the stone. Maxisil N Natural Stone Silicone Is easy to apply with good tooling properties.

*Please note that colour samples are not true to the actual colour. They are a guide only.

CHARACTERISTICS

Primary characteristics of Maxisil N Natural Stone Silicone are as follows:

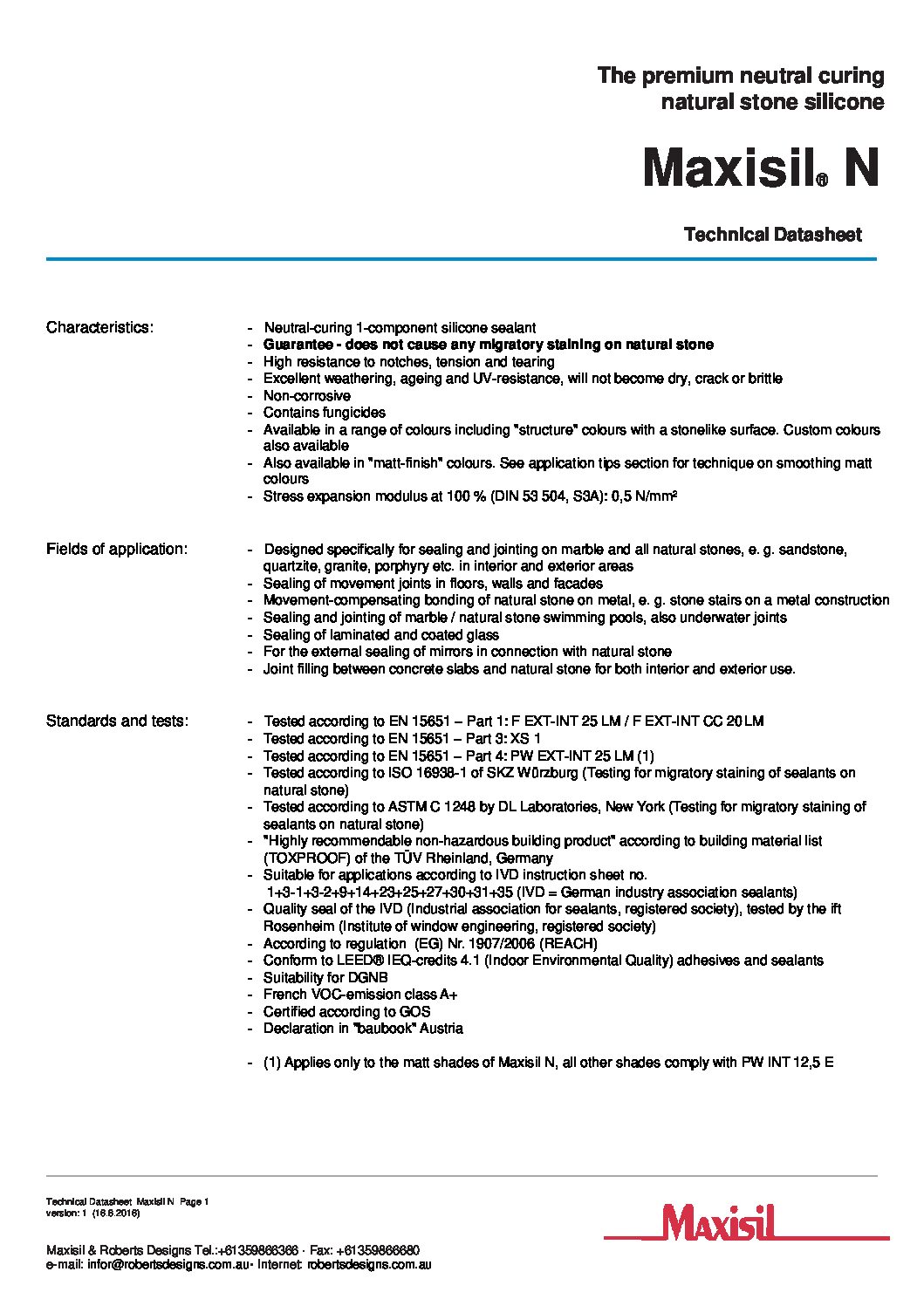

– Neutral-curing 1-component silicone sealant

– Guarantee – does not cause any migratory staining on natural stone

– High resistance to notches, tension and tearing

– Excellent weathering, ageing and UV-resistance, will not become dry, crack or brittle

– Non-corrosive

– Contains fungicides

– Available in a range of colours including “structure” colours with a stonelike surface. Custom colours also available.

– Also available in “matt-finish” colours. See application tips section for technique on smoothing matt colours.

– Stress expansion modulus at 100 % (DIN 53 504, S3A): 0,5 N/mm2

IMPORTANT INFORMATION

Before application, the user should ensure the materials in the contact area (solid, liquid and gaseous) are compatible with the sealant and also each other, so as they do not damage or alter (e. g. discolour) each other. If in doubt the user should consult each manufacturer of the surrounding substrates.

While curing, small amounts of acetic acid are released. Ensure good ventilation during application and curing.

After curing the product is completely odourless, physiologically harmless and unmodified.

The required vulcanization time prolongs with increasing thickness of the silicone layer. One-component silicones must not be used for full-surface bonding applications, unless special constructional prerequisites are met. If one-component silicones are to be used for thickness layers of more than 15 mm please contact our technical department beforehand.

Avoid contact with materials which contain bitumen and which release solvents, e. g. butyl, EPDM, neoprene, insulating- and bituminous paint.

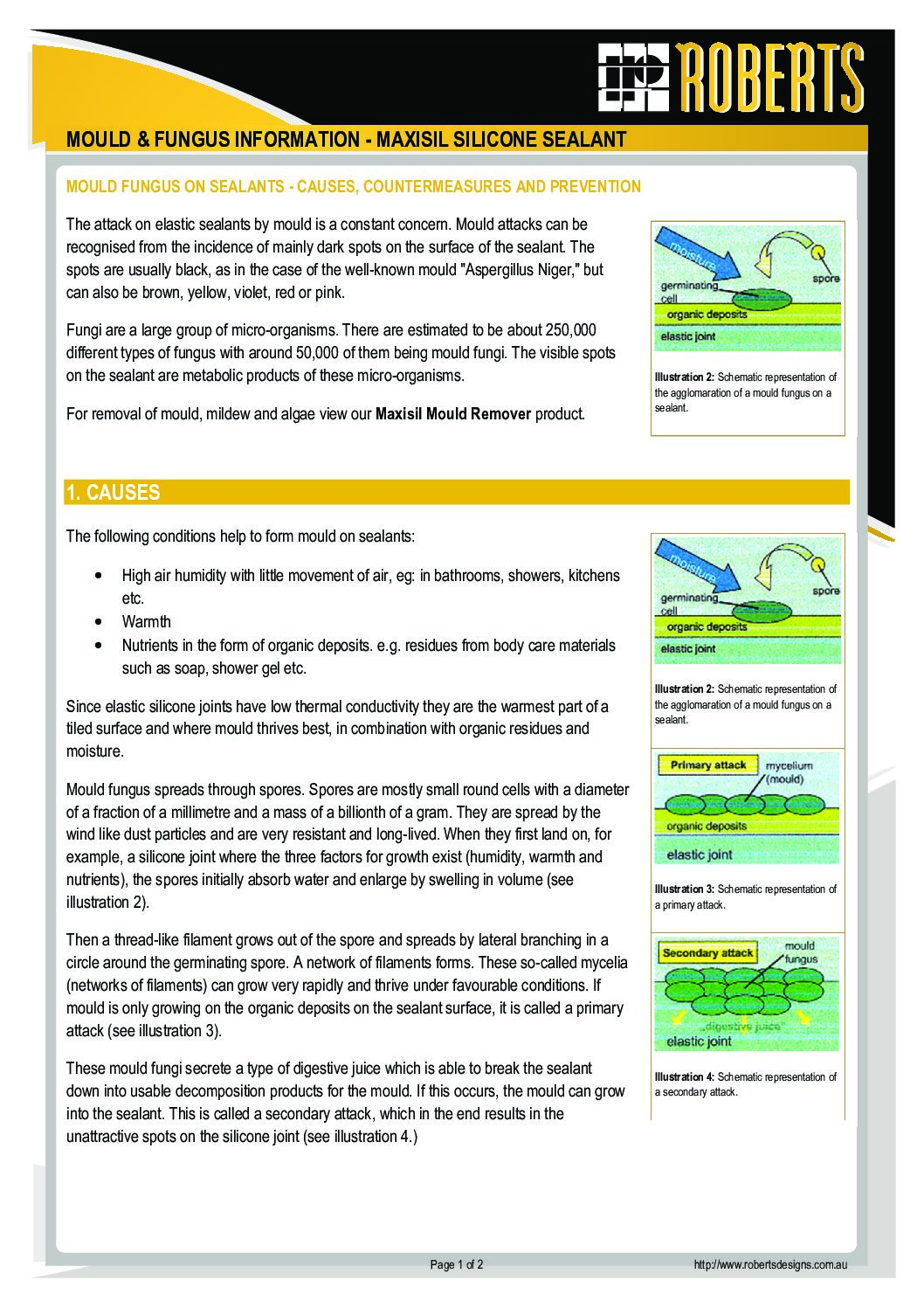

When restoring joints contaminated with mould, the existing elastic sealant must be removed completely. Before re-jointing, the affected joint areas are to be treated with Maxisil Anti-Mildew Spray to remove existing fungal spores. Otherwise a new mould attack may again occur in the joints, despite the mould protection technology of the sealant.

FIELDS OF APPLICATION

– Designed specifically for sealing and jointing on marble and all natural stones, e. g. sandstone, quartzite, granite, porphyry etc. in interior and exterior areas

– Sealing of movement joints in floors, walls and facades

– Movement-compensating bonding of natural stone on metal, e. g. stone stairs on a metal construction – Sealing and jointing of marble / natural stone swimming pools, also underwater joints

– Sealing of laminated and coated glass

– For the external sealing of mirrors in connection with natural stone

– Joint filling between concrete slabs and natural stone for both interior and exterior use.

PRETREATMENT for Maxisil N Natural Stone Silicone

All adherent surfaces must be clean of any contaminant such as release agents, preserving agents, grease, oil, dust, water, old adhesives or sealants and other substances, which could affect adhesion, should be removed.

Cleaning of non-porous substrates: Apply Maxisil Cleaner (airing time approx. 1 minute) using a clean, lint-free cotton cloth.

Cleaning porous substrates: Clean surfaces with steel-wire brush or a grinding disk to remove loose particles.

The adherent surfaces have to be clean, free from fat, dry and sustainable.

APPLICATION INFORMATION

With natural stone applications, take care not to spread the sealant beyond the joint area, as the sealant is difficult to remove.

When using a primer, apply to the substrate and allow to dry for approx 2 hours.

Once primer is dry, apply Maxisil N Natural Stone Silicone to the substrate.

Apply with an even method, avoiding air entrapment.

For best results the sealant should be smoothed with a smoothing agent and Applicator.

For best results use Maxisil Smoothtex N (part number RDX2019) and Maxisil Applicator (part number RDXA3000).

For backfilling of joints please use a closed cell PE foam rod.

When tooling off matt finish colours with Maxisil Smoothtex N Smoothing Agent – please be aware:

• The joint should be tooled off once, with a smoothing tool emmersed in Maxisil Smoothtex N.

• Do not make repeated passes with the smoothing tool.

• This will avoid polishing the matt surface !

• For best results use Maxisil Smoothtex N Smoothing Agent (undiluted).

• Wash / remove excess agent immediately from the joint area.

• We do not recommend the use of usual smoothing agents (e. g. dishwashing detergents etc.) as they have a high probability of staining some marble and natural stone.

• Due to many possible influences during and after application, we recommend to first conduct a trial on the substrate and bonding area.

• Please observe the recommended shelf life, printed on the packaging.

The date printed is a “best before” indication.

We recommend to store our products unopened and in original packaging, in a dry cool place (< 60 % RAH) at temperatures of +15 °C up to +25 °C. If the products are stored and / or transported at higher temperatures / humidity for long periods (some weeks), shelf life / material performance can be reduced, causing a change in material characteristics.