Description

Loctite 263 High Strength Threadlocker

Available in 10ml, 50ml and 250ml Size Options

Description

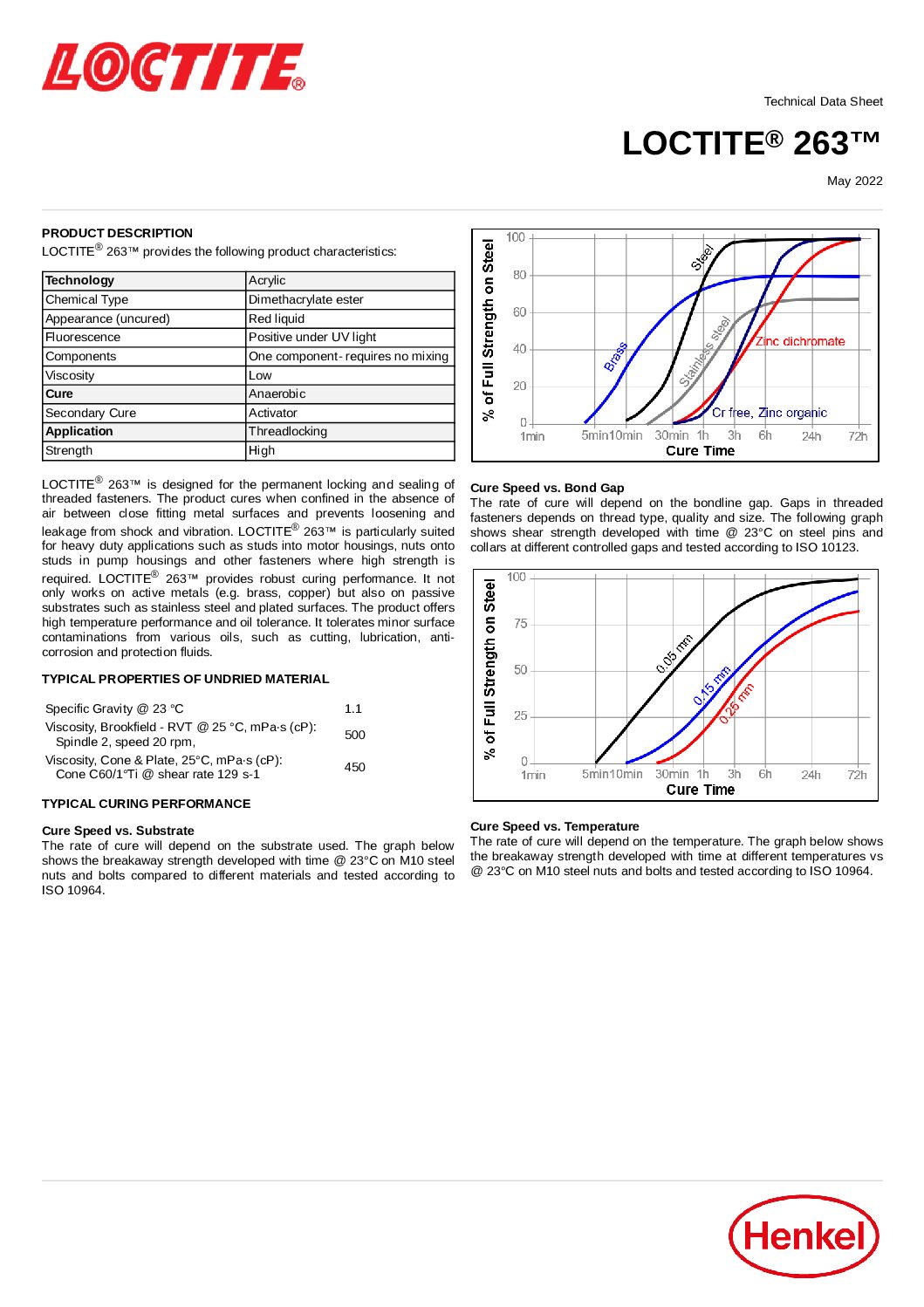

Loctite 263 High Strength Threadlocker (Red Coded) is a primerless threadlocker for permanently locking and sealing bolts, nuts and studs to prevent loosening due to vibration. Loctite 263 High Strength Threadlocker works on all metals, including passive substrates such as stainless steel, aluminum and plated surfaces without the use of primer. Suitable for use on most oil-coated, “as-received” fasteners without cleaning.

Features and Benefits

• Loctite 263 High Strength Threadlocker is ideal for heavy duty applications, such as studs into

motor housings, where high strength is required

• Prevents fastener loosening and leakage from shock and vibration

• Permanent locking and sealing of threaded fasteners – removable with heat

• Requires heat for disassembly

• High temperature performance (up to 182°C / 360°F) and oil tolerance

Technical Information

Agency approvals / certificates / specifications – NSF/ANSI 61

Application method, Dispense System, Manual

Application temperature -55.0 – 180.0 °C (-65.0 – 360.0 °F )

Applications, Threadlocking

Breakaway torque, M10 Steel Nuts/Bolts 33.0 N·m (290.0 in./lb. )

Colour, Red

Cure type – Anaerobic Cure

Fixture time 10.0 min.

Key Characteristics

- Disassembly: With Heat

- Fluorescent

- General Purpose

- Oil Tolerant

- Primerless

Strength: High Strength

Physical form, Liquid

Prevail torque, M10 Steel Nuts/Bolts 33.0 N·m (290.0 in./lb. )

Recommended for use with – Metal, Metal: Passive Metal

Specific gravity, @ 25.0 °C 1.1

Viscosity, 20 RPM 500.0 mPa·s (cP)

How to Use

1. Preparation – Cleaning

Loctite 263 High Strength Threadlocker is suitable for use on most “as-received” fasteners with light coatings of corrosion prevention oils without cleaning. However, for heavily oiled or contaminated fasteners, it is recommended to use LOCTITE® SF 7070 to degrease and clean surfaces prior to applying Loctite 263 High Strength Threadlocker.

2. Preparation – Activation

If cure speed is too slow due to passive metals (stainless steel, aluminum and plated metals) or low temperature (below 5°C), use LOCTITE SF 7649 activator. Allow to dry.

3a. Application – Through Hole

Apply a few drops of Loctite 263 High Strength Threadlocker liquid to the thread engagement area. Assemble nut and tighten to proper torque.

3b. Application – Blind Hole

Apply several drops of Loctite 263 High Strength Threadlocker liquid into lower third of blind hole, as well as a few drops onto male threads, and then install male threads. Tighten to proper torque.

4. Assembly

Assemble and tighten to proper torque requirement. If several bolts are being assembled, torque them down to the correct value within the fixture time window.

5a. Disassembly – Hand Tools

Disassemble with standard hand tools.

5b. Disassembly – Heat

If disassembly is not possible using normal hand tools, apply localized heat to approximately 500°F/260°C. Disassemble while hot with standard hand tools.

Equipment

For manual dispensing, the use of LOCTITE® EQ Pro Pump (for 50ml and 250ml bottles) or LOCTITE®Peristaltic Hand Pumps (50 ml or 250 ml versions) is recommended to ensure a consistent application volume.

Hint

For the disassembly of corroded or seized parts, use LOCTITE® LB 8040 Freeze and Release.