Description

LITOKOL LITOELASTIC EVO – 5kg and 10kg

GENERAL

Litokol Litoelastic EVO is a white two-component flexible reactive adhesive, water and solvent free, with high water resistance. Component A consists of synthetic resins, inert fillers with fine granulometry and specific organic additives. Part B consists of an innovative organic catalyst. Once mixed together, the two components form an easily workable, thixotropic and particularly fluid paste that facilitates the work of installers.

TECHNICAL

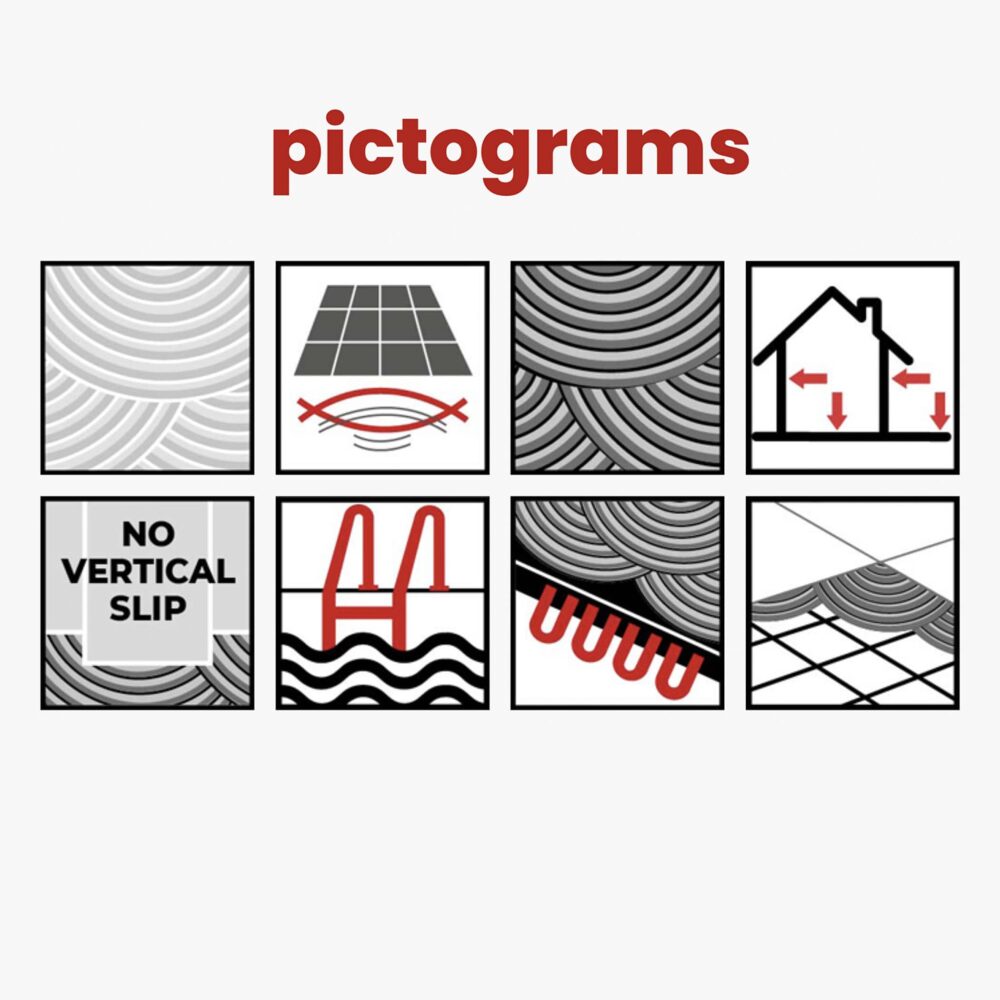

LITOKOL LITOELASTIC EVO IS A HIGH-PERFORMANCE FLEXIBLE REACTIVE ADHESIVE WITH NO VERTICAL SLIP FOR THE INSTALLATION OF ALL TYPES OF CERAMIC AND PORCELAIN TILES ON INTERIOR AND EXTERIOR WALLS AND FLOORS. SUITABLE FOR OVERLAYING AND UNDERFLOOR HEATING. PRODUCT WITH VERY LOW VOLATILE ORGANIC COMPOUND EMISSION RATE.

ADVANTAGES AND FEATURES

Litokol Litoelastic EVO Is a product having a very low volatile organic compound (VOC) emission rate.

It complies with class EC1PLUS according to the EMICODE protocol and class A+ (Émission dans l’air intérieur – French Regulations).

Bonding on all types of ceramic, porcelain and mosaic tiles, in interiors on floors and walls.

Allows the installation of ceramic, porcelain and mosaic wall coverings without the need for plastic spacers.

Suitable for installation on heating screeds.

Suitable for overlaying on existing flooring.

Suitable for interior and exterior floor and wall applications, even in severe operating conditions.

The special additives give the product a very fluid texture and facilitate application using a notched trowel Reactive adhesive formulated with special raw materials ensuring the product’s exceptional ease of application, unique to its kind.

Multipurpose adhesive suitable for bonding different types of coverings such as ceramics, porcelain stoneware, large thin slabs, including those with backing, clinkers, vitreous or ceramic mosaics, natural or reconstituted stones, including moisture-sensitive stones, even on non-traditional substrates such as metal, wood, fibreglass, PVC, linoleum.

Product with high deformation and excellent water-resistance properties.

Suitable for one-step waterproofing and installation of ceramic and porcelain tiles or mosaics in shower enclosures or indoor wet areas.

Product exempt from restrictions for road, sea, air and rail transport.

The super white colour enhances the shades of vitreous mosaics.

PACKAGING

Litokol Litoelastic EVO Is available in:

5kg buckets (A+B), and

10kg buckets (A+B)

INTENDED USES

Intended uses

Interiors – exteriors

Floors and walls

Underfloor heating

Façades

Overlaying

Terraces and balconies Residential, public, commercial building

Ceilings

Tanks, swimming pools, fountains SPA and Hammam

Indoor wet areas (bathrooms, shower enclosures)

Industrial floors

Suitable materials

Ceramic and porcelain tiles

Thin laminated stoneware slabs Recomposed stone made with resin or cement

Terracotta – Clinker

Marble – Granite – Stone

Natural stones

Slabs 320×160 cm

Large sizes

Porcelain stoneware

Ceramic and vitreous mosaics Insulating panels

Polystyrene panels

Soundproof panels

Elements in cement

Glass wool

Rockwool

Cork

Flexible natural stone sheets

Slabs with resin backing

Suitable substrates

Cement screeds Self-levellers

Skim coats

Existing tiles

Waterproofing systems Underfloor heating systems Concrete

Gypsum

Fibre cement slabs Gypsum and anhydrite Aerated concrete Plasters

Insulating panels Lightweight panels Separation membrane Wood

Metal

PVC

Fibreglass

Linoleum

Parquet

Interior floors in residential and public/commercial settings (pedestrian areas)

Cement or Litocem/Litocem Pronto-based non-heating screeds – any tile side width

Cement or Litocem/Litocem Pronto-based heating screeds – any tile side width

Sulphate-based (anhydrite) non-heating screeds – any tile side width

Sulphate-based (anhydrite) heating screeds – any tile side width

Cast-in-place concrete (2) – any tile side width

Pre-cast concrete – up to 120cm tile side width

Pre-existing tiled, mosaic, stone, agglomerate substrates (3) – any tile side width

Pre-existing wood, PVC, resin substrates – any tile side width

Pre-existing substrates with organic adhesive residue (4) – any tile side width

Substrates waterproofed with Hidroflex, Aquamaster, Elastocem, Coverflex, Litoproof Plus – any tile side width

Wood or metal substrates – any tile side width

Interior floors in public/commercial and industrial settings with heavy traffic

Cement or Litocem/Litocem Pronto-based non-heating screeds – any tile side width

Cast-in-place concrete (2) – any tile side width

Pre-cast concrete – up to 120 cm side width

Pre-existing tiled, mosaic, stone, agglomerate substrates (3) – any tile side width

Pre-existing wood, PVC, resin substrates – any tile side width

Pre-existing substrates with organic adhesive residue (4) – any tile side width

Substrates waterproofed with Litoproof Plus – any tile side width

Substrates waterproofed with Hidroflex, Aquamaster, Elastocem, Coverflex, Litoproof Extreme – any tile side width

Wood or metal substrates – any tile side width

Interior walls in residential, public/commercial and industrial settings

Lime/cement plaster – any tile side width

Gypsum-based plaster any tile side width

Cast-in-place concrete (2) – any tile side width

Pre-cast concrete – any tile side width

Pre-existing tiled, mosaic, stone substrates (3) – any tile side width

Substrates waterproofed with Hidroflex, Aquamaster, Elastocem, Coverflex, Litoproof Plus – tile side width

Fibre cement and cement panels – any tile side width

Waterproof and non-waterproof gypsum slabs – any tile side width

Elements in autoclaved aerated concrete (6) – any tile side width

Thermal insulated and soundproof panels – Lightweight panels – any tile side width

Exterior floors in residential, public/commercial and industrial settings

Cement or Litocem/Litocem Pronto-based non-heating screeds – any tile side width

Cast-in-place concrete (2) – any tile side width

Pre-cast concrete – any tile side width

Pre-existing tiled, mosaic, stone, agglomerate substrates (3) – any tile side width

Substrates waterproofed with Aquamaster, Elastocem, Coverflex, Litoproof Extreme – any tile side width

Substrates waterproofed with resins with quartz surface treatment – any tile side width

Wood or metal substrates – up to 90cm tile side width

Exterior walls

Lime/cement plaster – any tile side width

Cast-in-place concrete (2) – any tile side width

Pre-cast concrete – any tile side width

Pre-existing tiled, mosaic, stone, agglomerate substrates (3) – any tile side width

Substrates waterproofed with Aquamaster, Elastocem, Coverflex – any tile side width

Fibre cement panels – any tile side width

Wood or metal substrates – any tile side width

(1) After treatment with Primer C or Primer X94. Maximum humidity = 0.5%.

(2) Curing time: minimum 6 months.

(3) After cleaning and degreasing with Litoscrub EVO.

(4) After treatment with the adhesion promoter Prepara Fondo EVO.

(5) After treatment with Primer C or Primer X94 for non-waterproof gypsum.

(6) After treatment with Primer X94.

PRE-INSTALLATION

The substrates must be clean, solid, compact, crack-free, properly cured and without rising damp.

Use of primer:

• Excessively porous and absorbent or powdery substrates must be treated with the consolidating primer Primer C. The application of Primer C on absorbent surfaces improves the fluid application of the mix while also improving the level of adhesion

• Smooth and compact substrates such as smoothed concrete, existing ceramic or agglomerate coverings, must be treated with the adhesion promoter primer Prepara Fondo EVO after being suitably degreased with specific detergents such as Litoscrub EVO

• In the case of anhydrite screeds, check for the presence of a suitable vapour barrier in order to prevent rising damp. Use a carbide method hygrometer to check that the residual humidity is less than 0.5%. The surface must be sanded and treated with Primer C

• Any cracks must be repaired with Multifondo EVO, sprinkling the fresh surface with sand or dried quartz with granulometry 0.4-1 mm

In any case, the respective technical data sheets must be consulted for correct use of the indicated products.

Expansion joints

Check that the perimeter, expansion, divider and structural elastic joints have been correctly designed and prepared. Divider joints are normally required for sections equal to 50 m2 or 25/30 m2 in the case of underfloor heating.

In areas with surfaces less than 50 m2 expansion joints must nonetheless be inserted along each of the door thresholds.

MIX RATIO

Component A 92.6 parts by weight – Component B 7.4 parts by weight. The two components are pre-batched in their respective packaging.

PREPARING THE MIX

Pour part B (catalyst) onto part A (paste).

We recommend pouring all the catalyst contained in the bag.

Mix, preferably using an electric drill with mixing paddle at low speed (≈ 300/min.) until a consistent mix is obtained without lumps.

Hand mixing is not recommended.

The two components are pre-batched in their packaging, thus preventing mixing errors.

APPLICATION

Spread the Litokol Litoelastic EVO mixture onto the substrate using the smooth part of the trowel to create a layer approximately 1 mm thick.

Immediately afterwards, spread additional Litokol Litoelastic EVO using the notched part of the trowel.

The trowel notch size will depend on the size of the tiles.

A back coverage of 65-70% is nonetheless required for interior installations, and 100% for exterior installations, floors subject to heavy traffic or mechanical stress, and swimming pools.

The tiles must be laid on the adhesive when fresh, firmly pressed to ensure good contact.

The tiles must be installed with joint widths suitable for their size.

Take account of any expansion, perimeter, divider or structural joints.

Leave a space of at least 5 mm near walls or any surface elevations.

In the case of single-step waterproofing and installation of ceramic materials or mosaics in shower enclosures or indoor wet areas, at least 1 mm of product must first be applied to the relevant area using a smooth trowel.

After setting (about 24 hours), spread the product using a notched trowel to install the ceramic materials.

FOCUS

Marble, natural and recomposed stones

Materials subject to deformation or stains due to water absorption require a quick-setting (C2F) or reactive (R2) adhesive. Marble and natural stones, even if similar in nature, may have different characteristics. In case of doubt, contact the Litokol S.p.A. Technical Help Service for detailed information or to perform a laboratory test. Natural stone slabs with reinforced backing (resin, mesh, etc.) or specific treatments (for example anti-rising damp, etc.), unless otherwise prescribed by the manufacturer must be tested for compatibility with the adhesive. Before installation, check for any traces of dirt or material deposits on the back of the slabs. If so, these must be removed.

Façades

For exterior wall installations (H>3 m) where tiled surfaces are subject to high levels of tension in expansion joints due to the variations in air temperature and relative humidity and considering the safety risks posed by any eventual detachments, it is recommended to consult the Litokol S.p.A Technical Help Service in order to precisely define the safest type of installation. In accordance with standard UNI 11493 – point 7.13.7), follow these general instructions: the substrate must guarantee a cohesive tensile strength ≥ 1.0 N/mm2. For coverings with side > 30 cm the designer must evaluate the potential need to use suitable mechanical fasteners for safety purposes. Always spread the adhesive directly onto the back of the material also.

Underfloor heating

After at least 4 days from installation of the screed developed with Litocem or Litocem Pronto, the heating system can be used with a variable supply water temperature between +20°C and +25°C, kept constant for at least 3 days.

Then set the maximum design temperature and hold it for another 4 days. At the end of this cycle, bring the screed back to ambient temperature and install the covering (see standard EN 1264-4).

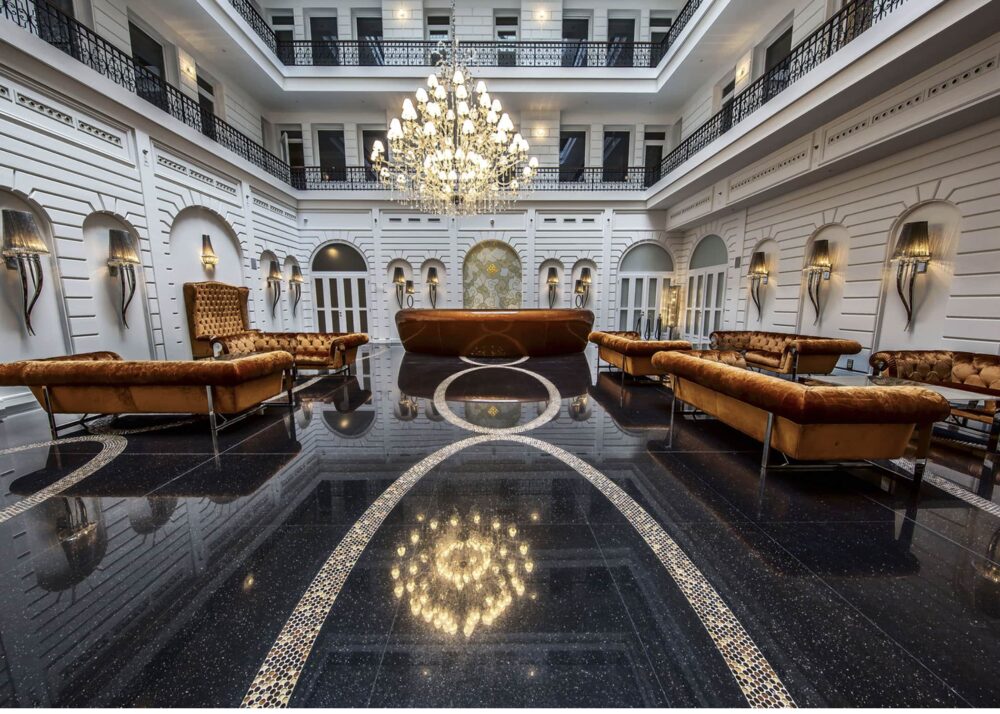

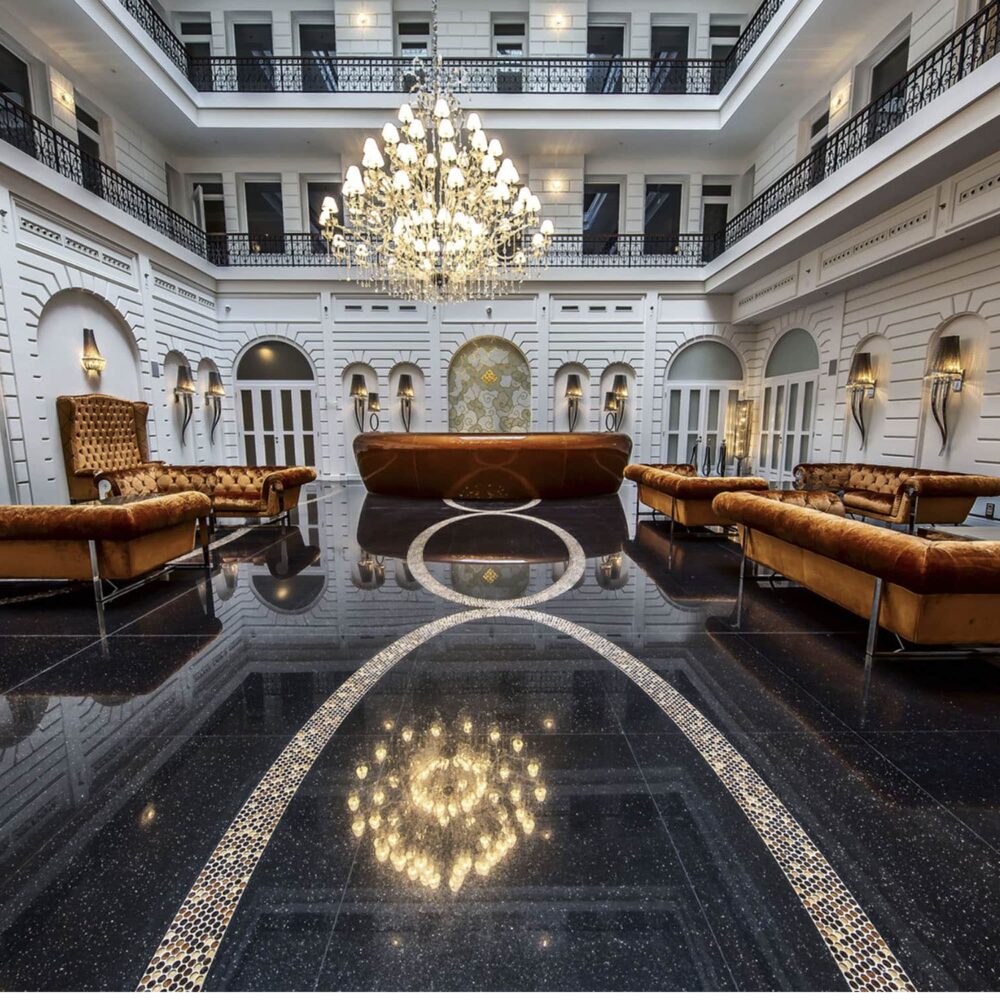

Swimming pools

Litokol Litoelastic EVO can be applied directly on the concrete substrate or Elastocem, Coverflex, Aquamaster and Litoproof Extreme elastic waterproofing membranes.

Following is a list of precautions that must be followed when installing the coverings:

Respect the concrete curing time (minimum 6 months)

For underground tanks, adopt preventive measures against possible capillary rising damp, which may cause the detachment of the waterproofing membrane applied inside the tank, for example on drains along the side walls of the excavations or waterproofing constituted by osmotic mortars such as Osmogrout

Rectify the surfaces using suitable cementitious mortars such as Litoplan Smart

Waterproof the internal surfaces of the tank with flexible waterproof membranes resistant to contact with chlorinated water such as Elastocem, Coverflex, Aquamaster and Litoproof Extreme

It is advisable to perform a hydraulic seal test before installing the covering

Bonding of insulation panels

It can be applied either with a notched trowel or in certain points, nonetheless in accordance with the product’s open time.

In any case, the quantity of adhesive applied should be sufficient to ensure the panels are securely bonded.

The slabs must then be installed by applying adequate pressure to obtain a suitable level of adhesion.

TILE INSTALLATION

Coverings can be installed after at least 24 hours have passed since the last coat.

Ceramics, natural stones or mosaics can be installed with cementitious adhesives in class C2 or reactive in class R2 according to UNI EN 12004.

The choice of adhesive depends on the size of the tiles and expected operating conditions.

In the case of large tiles (side > 60 cm), it is preferable to use deformable adhesives in class S1 or highly deformable adhesives in class S2.

The tiles must be installed with a solid bed using the back-buttering technique, with joint widths suited to their size. For the correct choice of adhesive, refer to the technical data sheets of the products.

GROUTING

After tiling using Litokol Litoelastic EVO, joints can be grouted after approximately 6-8 hours in the case of wall tiles and after 24 hours in the case of floor tiles.

For grouting, it is possible to use the cementitious grouts Stylegrout 0-8, Stylegrout 3-20, Stylegrout Tech or the ready-to-use polymer mortar FillGood EVO, or, for grouting with special mechanical and chemical resistance, the two-component epoxy grouts Starlike® EVO or EpoxyÉlite EVO.

WARNINGS

• Spread Litokol Litoelastic EVO at temperatures between +10°C and +30°C inclusive

• Do not add lime, cement or other foreign materials to the product

• Respect the mix ratio

• Do not use Litokol Litoelastic EVO for applications not stated in this technical sheet

• Do not spread Litokol Litoelastic EVO with thickness greater than 10 mm

• To identify the adhesive most suitable to the requested type of application, it is recommended to consult the document “Synoptic table for choice of adhesives”

• Do not use Litokol Litoelastic EVO on floors that need to quickly set to light foot traffic

• If in doubt, contact the Litokol S.p.A Technical Help Service.

SAFETY INFORMATION

Consult the product safety data sheet, available on request. PRODUCT FOR PROFESSIONAL USE

ITEM SPECIFICATION

#Any type of ceramic and porcelain tiles, natural stones, vitreous or ceramic mosaics, resin agglomerates, thin slabs with and without backing, thin and flexible stone slabs with polyester and fibreglass support must be installed with a two-component reactive adhesive with no vertical slip in class R2T according to EN 12004, such as Litokol Litoelastic EVO by Litokol S.p.A.