Description

Mapei Ultralite S1 Flex White Adhesive

• 13.5kg Bag

• Call us for direct invoicing (03 9221 6222) – you save the 3% website Processing

One-component, high-performance, deformable, lightweight, white cementitious adhesive with no vertical slip, extended open time, and extremely high yield. Easy to apply by trowel with high back-buttering capacities for ceramic and stone tiles.

Ideal for large-format tiles.

Classification According to EN12004

Ultralite S1 Flex is a C2TES1-class cementitious (C), improved (2), slip-resistant (T), extended open time (E), deformable (S1) adhesive. The conformity of Ultralite S1 Flex is declared in TT certificate n. 21/32301609 and n. 21/32301610 issued by the APPLUS, LGAI Technological Center Bellaterra (Spain).

Where to Use

- Bonding all types and sizes of ceramic tiles (double-fired, single-fired, porcelain, clinker, terracotta, etc.) on interior and exterior substrates.

- Bonding all types of mosaic on interior and exterior surfaces, also in swimming pools.

- Bonding stone tiles on interior and exterior surfaces (as long as the stone material is not sensitive to moisture and staining).

- Bonding large format porcelain tiles, also thin porcelain tiles on floors, specifically on large surface areas: due to the high back-buttering capacity, the formation of voids between the substrate and the tile is limited.

- Bonding on interior and exterior walls, including exterior facades.

Application Examples

- Bonding ceramic tiles (porcelain, clinker, double-fired, single-fired, etc.), ceramic and glass mosaic, stone

tiles (as long as not sensitive to moisture) and thin and large format porcelain tiles on the following substrates: - Installing ceramic and natural stone tiles on existing floors (ceramic, marble, etc.) and after priming with

Eco Prim Grip. - Installing tiles on marine plywood, particleboard, existing wooden Floors (as long as they are stable) and after priming with Eco Prim Grip.

- Installing ceramic and natural stone tiles in balconies, terraces, flat roofs subject to direct sunlight and or

temperature swings. - Installing tiles on precast concrete walls and concrete substrates.

- Installing tiles in swimming pools and tanks.

- self-levelling compounds and screeds (including heated);

- stable and cured concrete floors;

- cementitious render and lime-mortar render;

- gypsum-based render (after the application of an acrylic primer such as Primer G or Eco Prim T Plus);

- plasterboard, walls made of fibre cement panels, precast wall panels;

- Mapeguard Board, multi-purpose construction panels;

- Mapelastic Smart, Mapelastic AquaDefense, Aquaflex WPU, or Mapegum WPS waterproofing membranes;

waterproofing and uncoupling, anti-fracture, membranes from the Mapeguard range.

Technical Characteristics

Ultralite S1 Flex is a white powder made of cement, selected graded sand and a high amount of synthetic resins, admixed with lightweight, natural aggregates that make the mix lighter, according to a special formula developed in MAPEI Research & Development labs.

Ultralite S1 Flex Zero is a product with very low emission of volatile organic compounds (VOC), which safeguards the health and safety of installers and final users. It is certified as EC1 Plus by the German

association GEV.

Ultralite S1 Flex helps earn important LEED credits.

Ultralite S1 Flex offers the following advantages:

- The special formulation used to manufacture Ultralite S1 Flex gives it a low density, a characteristic which offers two main advantages:

- Ultralite S1 Flex has a low viscosity, which makes application quicker and easier. Despite the above

characteristics, the thixotropic nature of Ultralite S1 Flex means there is no vertical slip when installing

tiles on walls, even with large-format tiles. - Its excellent back-buttering properties and thixotropic consistency make Ultralite S1 Flex particularly

suitable for laying thin porcelain tiles. The application of Ultralite S1 Flex using the back-buttering

technique on flat substrates ensures that there are absolutely no voids in the adhesive on the back of the

tiles, thus avoiding the risk of fracture when in service. - Its excellent non-slip properties also make it particularly easy and safe to install tiles on vertical surfaces

- Bags of Ultralite S1 Flex have the same volume but weigh less (13.5 kg) than bags of conventional

cementitious adhesive (20 kg). This means less effort for the workers, as the bags are easier to handle

on the construction site and storage warehouses. Furthermore, lightweight leads to clear benefits in

terms of reduced transport costs: indeed, one pallet of Ultralite S1 Flex Zero weighs 750 kg while one

pallet of conventional adhesive weighs 1250 kg.

- higher yield: each 13.5 kg bag of Ultralite S1 Flex has approximately the same yield (in terms of

square metres of tiles installed with the same type of trowel, installation technique and substrate) as

that of 20 kg bags of conventional MAPEI cementitious adhesives

When mixed with water, Ultralite S1 Flex forms a mortar with the following characteristics:

- excellent capacity of absorbing deformation in the substrate and tiles;

- excellent back-buttering properties;

- perfect bond to all materials normally used in the building industry;

- particularly extended adjustment and open time to make installation easier.

Recommendations

Do NOT use Ultralite S1 Flex in the following cases:

- on metal, rubber, PVC and linoleum substrates.

- for slabs of marble and natural stone subject to efflorescence or staining on metal.

- for natural or agglomerate stone subject to moisture expansion.

- when the floored surface must set to foot traffic quickly.

Do not add water to the mix once it starts to set,

Application Procedure

REFER TO TECHNICAL DATA SHEET PDF (See Specifications – Below)

Grouting and Sealing

Tile joints may be grouted after 4 to 8 hours on walls and after 24 hours on floors.

Use a MAPEI cementitious or epoxy grout, available in a wide variety of colours.

Expansion Joints must be sealed using a suitable MAPEI sealant.

If necessary, clean, maintain and protect the surfaces using the specific products from the UltraCare range.

Set to Light Foot Traffic

The floors are set to light foot traffic after approximately 24 hours.

Ready for Use

Surfaces are ready-for use after approximately 14 days.

Tanks and swimming pools can be filled after waiting at least 21 days.

Cleaning

Clean tools and containers with plenty of water while Ultralite S1 Flex is still fresh.

Clean the surfaces of tiles with a damp cloth before the adhesive hardens.

Packaging

Grey Ultralite S1 Flex is available in 13.5 kg paper bags.

Consumption

0.8 kg/m² per mm of thickness, equal to:

- 1.5 kg/m² for the installation of uncoupling or waterproofing membranes (using a 5 mm notched trowel);

- 2-3.5 kg/m² for the installation of tiles (depending on the type of trowel selected according to the size of the tiles)

NOTE:

Coverages shown are approximate and are given for estimating purposes only.

Actual job-site coverages may vary according to the tile size and thickness, job conditions and setting practices.

For coverage values contact MAPEI’s Technical Services Department on 1800 652 666.

Storage

Ultralite S1 Flex may be stored for 12 months in its original packaging in a dry area.

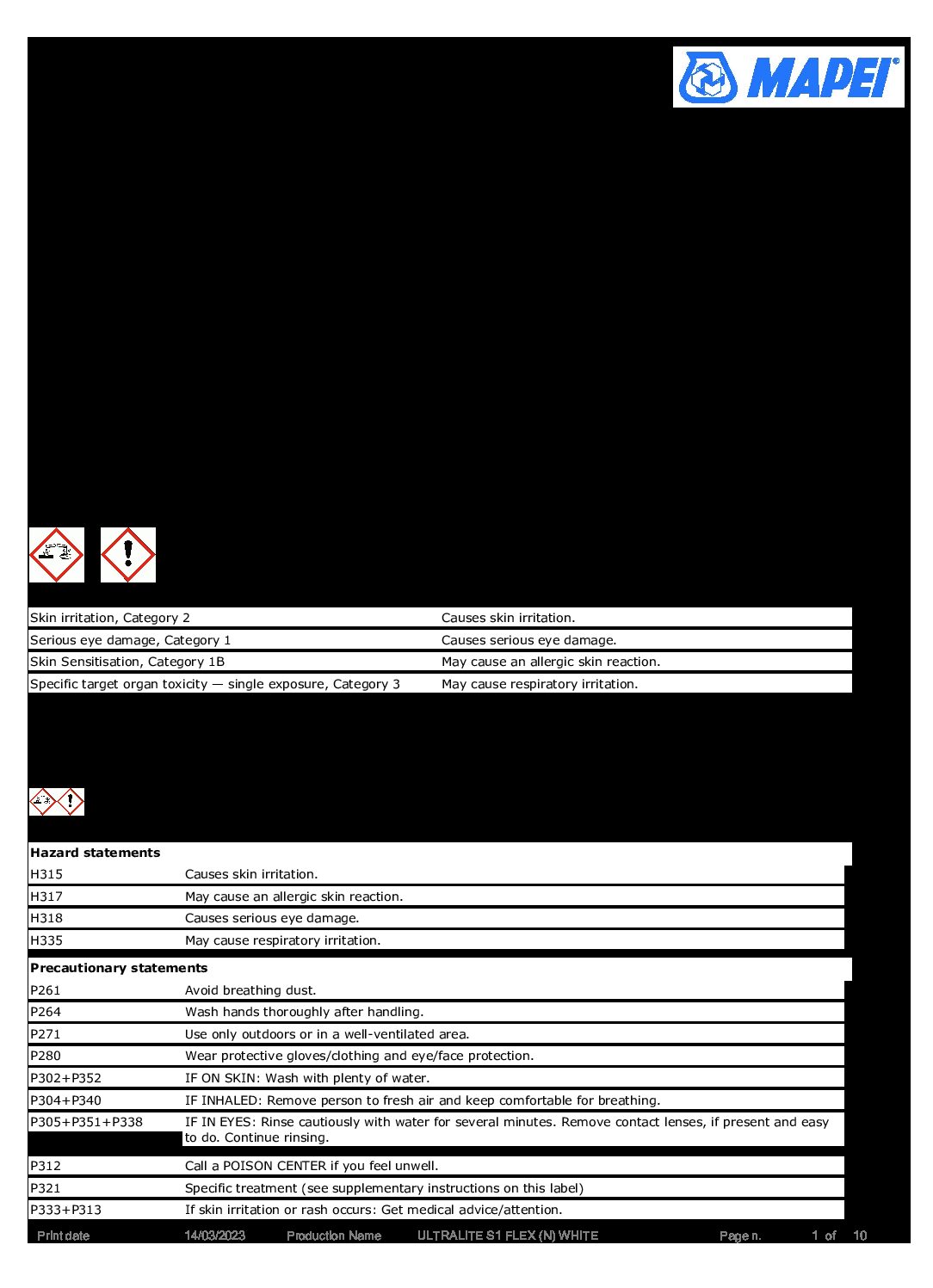

Safety Instructions

Instructions for the safe use of Mapei products can be found on the latest version of the Safety Data Sheet, available from the Mapei website at www.mapei.com.au

PRODUCT FOR PROFESSIONAL USE