Description

LITOKOL LITOLIV S40 ECO – 20kg

GENERAL

Litokol Litoliv S40 ECO is a ready-mixed cementitious powder self-leveller made from special hydraulic binders, inert fillers of selected granulometry, organic additives and synthetic fibres.

Once mixed with water, Litokol Litoliv S40 ECO is characterised by an excellent self-levelling capacity and ease-of-application by hand or screw-pump plastering machine with variable thickness between 3 and 40 mm.

TECHNICAL

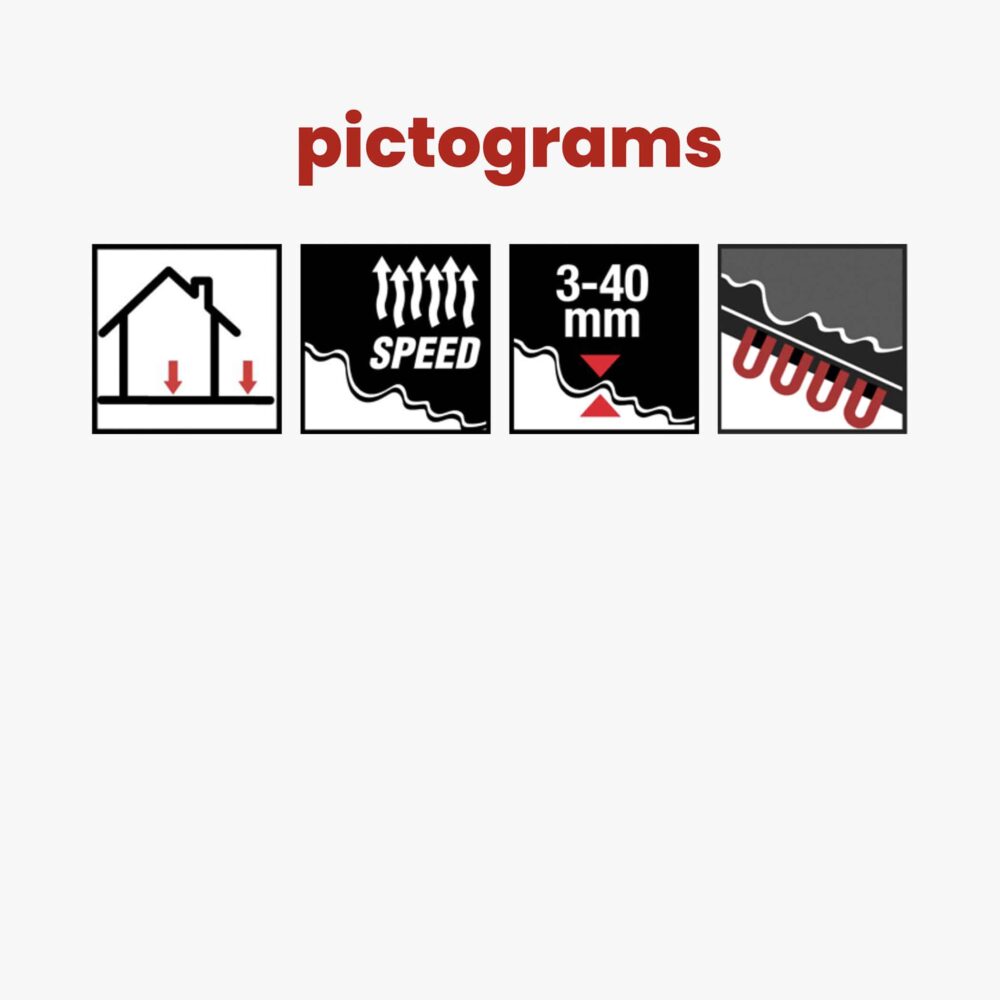

LITOKOL LITOLIV S40 ECO IS A QUICK-SETTING AND DRYING CEMENTITIOUS SELF- LEVELLER FOR LEVELLING OF SUBSTRATES WITH THICKNESS BETWEEN 3 AND 40 mm. SUITABLE FOR UNDERFLOOR HEATING. FOR INTERIORS AND EXTERIORS. FIBRE-REINFORCED. PRODUCT WITH VERY LOW VOLATILE ORGANIC COMPOUND EMISSION RATE.

ADVANTAGES AND FEATURES

Litokol Litoliv S40 ECO:

• Product with very low volatile organic compound (VOC) emission rate. Complies with class EC1PLUS according to the EMICODE protocol and class A+ (Émission dans l’air intérieur – French Regulations)

• High abrasion resistance

• Quick setting and drying

• Development of screeds with incorporated heating coils without the need for fluidifying additives

• Excellent self-levelling effect

• Suitable for interior and exterior applications.

• Suitable for substrate levelling in electric and hot water underfloor heating

• Excellent adhesion on traditional cementitious substrates

• No shrinkage during setting, which prevents cracking phenomena

• Fibre-reinforced product with improved resistance to expansion stresses in the presence of underfloor heating

FIELDS OF APPLICATION

Intended uses of Litokol Litoliv S40 ECO:

Suitable for levelling and eventing out interior and exterior horizontal surfaces with thickness between 3 and 40 mm in a single coat.

Typical applications include:

• Levelling of cement screeds in indoor areas, also developed with Litocem or Litocem Pronto

• Levelling on heating screeds

• Levelling on sulphate/anhydrite-based screeds

• Levelling on existing floors made with ceramics, natural stone and agglomerate coverings

• Levelling of concrete slabs

PRE-INSTALLATION

The substrates must be clean, solid, compact, crack-free, properly cured and without rising damp.

Use of primer:

• Excessively porous and absorbent or powdery substrates must be treated with the consolidating primer Primer C. The application of Primer C on absorbent surfaces improves the fluid application of the mix while also improving the level of adhesion

• Smooth and compact substrates such as smoothed concrete, existing ceramic or agglomerate coverings, must be treated with the adhesion promoter primer Prepara Fondo EVO after being suitably degreased with specific detergents such as Litoscrub EVO

• In the case of anhydrite screeds, check for the presence of a suitable vapour barrier in order to prevent rising damp. Use a carbide method hygrometer to check that the residual humidity is less than 0.5%. The surface must be sanded and treated with Primer C

• Any cracks must be repaired with Multifondo EVO, sprinkling the fresh surface with sand or dried quartz with granulometry 0.4-1 mm

In any case, the respective technical data sheets must be consulted for correct use of the indicated products.

Expansion joints

Check that the perimeter, expansion, divider and structural elastic joints have been correctly designed and prepared. Divider joints are normally required for sections equal to 50 m2 or 25/30 m2 in the case of underfloor heating.

In areas with surfaces less than 50 m2 expansion joints must nonetheless be inserted along each of the door thresholds.

MIX RATIO

20 kg (1 bag) – Water 4.8 l (24%)

PREPARING THE MIX

Pour the right quantity of water, depending on the application, into a clean container and slowly add Litokol Litoliv S40 ECO powder, stirring with an electric drill with mixing paddle until a consistent mix is obtained without lumps.

Let the mix rest for about 3 minutes and then briefly mix again for a few seconds.

The pot life is about 20 minutes at a temperature of +23°C, therefore it is advisable to mix only the quantity of material that can be applied within this period of time.

Do not use quantities of mixing water greater than those indicated to avoid product shrinkage during curing and the lowering of the final mechanical properties.

Do not add more water to the mix once setting has begun.

If the product is applied with a plastering pump with vertical mixer, the quantity of mixing water must be the same as for manual preparation, and mixing must continue until complete homogenisation before spreading the mix.

APPLICATION

Pour the Litokol Litoliv S40 ECO mixture directly onto the substrate.

Spread the product using a smooth steel trowel or rubber floor squeegee to obtain the required thickness.

The product can also be applied using a plaster pump.

Ceramic and porcelain tiles, wood, resilient or textile flooring can then be installed after about 12-24 hours depending on the applied thickness and ambient temperature.

When installing wood flooring, apply a minimum thickness of at least 3 mm and check the humidity using a carbide method hygrometer before bonding (maximum humidity = 2%).

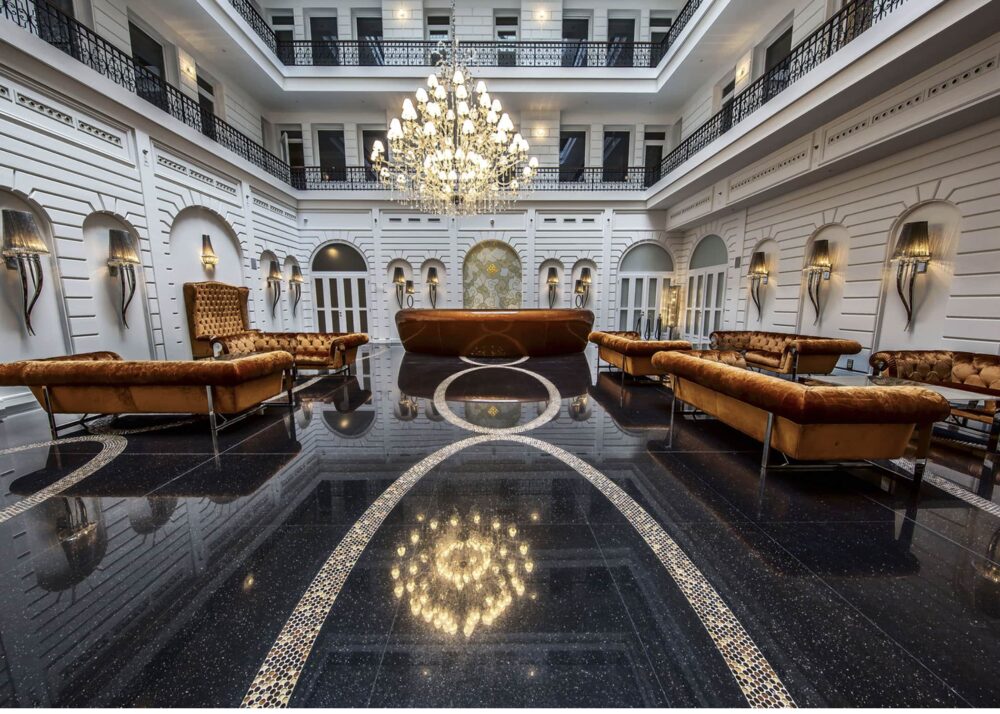

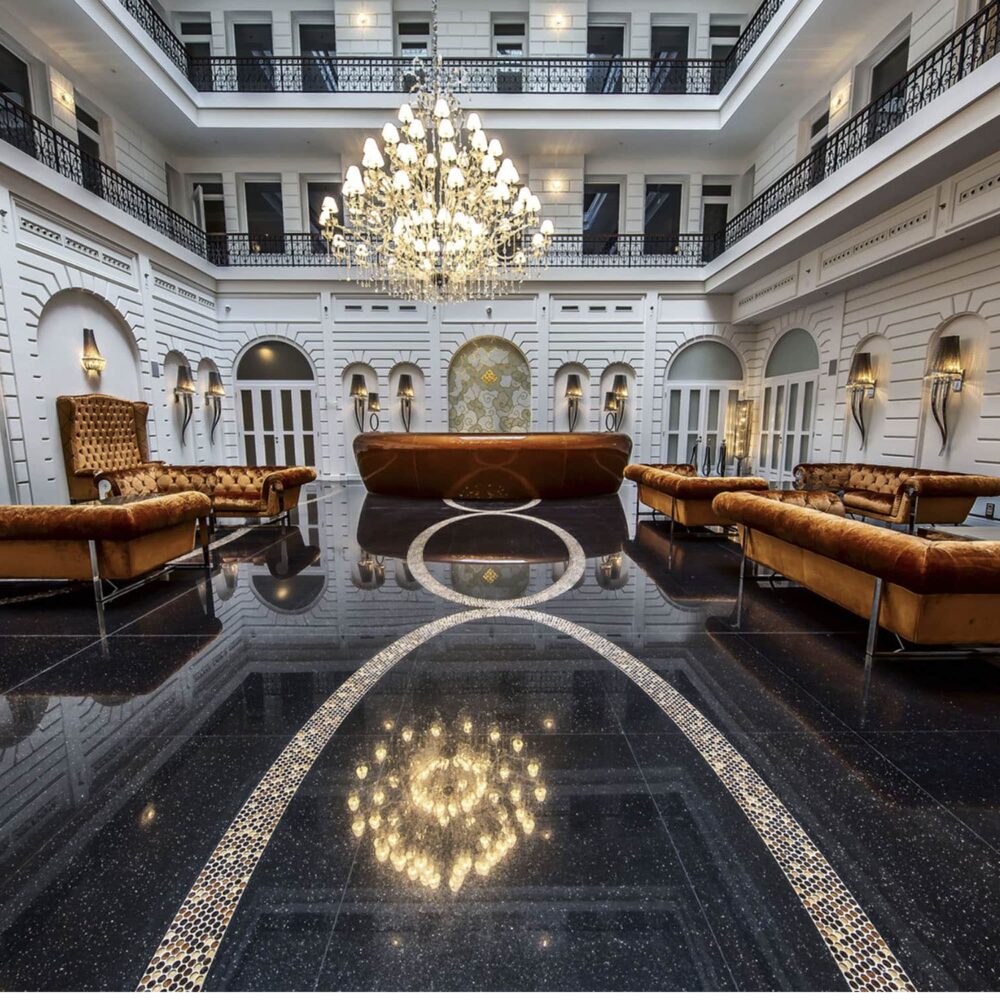

TILE INSTALLATION

Coverings can be installed after at least 24 hours have passed since the last coat.

Ceramics, natural stones or mosaics can be installed with cementitious adhesives in class C2 or reactive in class R2 according to UNI EN 12004.

The choice of adhesive depends on the size of the tiles and expected operating conditions.

In the case of large tiles (side > 60 cm), it is preferable to use deformable adhesives in class S1 or highly deformable adhesives in class S2.

The tiles must be installed with a solid bed using the back-buttering technique, with joint widths suited to their size. For the correct choice of adhesive, refer to the technical data sheets of the products.

WARNINGS

• Spread Litokol Litoliv S40 ECO at temperatures between +5°C and +35°C inclusive

• Do not add lime, cement or other foreign materials to the product

• Do not use the product on damp surfaces or surfaces subject to rising damp

• The pot life is about 20 minutes at a temperature of +23°C. Be sure to mix only the quantity of product that can

actually be used within this period of time

• Use the correct amount of water in the mix. Too much water may result in longer setting times and increase the

risk of cracks and flaking, powdery and crumbly surfaces

• Do not use the product in the presence of strong air currents

• Do not use the product for applications not stated in this technical sheet

• If in doubt, contact the Litokol S.p.A Technical Help Service.

SAFETY INFORMATION

Consult the product safety data sheet, available on request. PRODUCT FOR PROFESSIONAL USE

ITEM SPECIFICATION

#The certified high-resistance rectification of the substrate with thickness from 3 to 40 mm will be carried out with a mineral fibre-reinforced quick-setting self-leveller compliant with standard EN 13813, class CT-C20-F5, such as Liticol Litoliv S40 ECO by Litokol S.p.A., suitable for the subsequent installation of ceramics after 12 hours and of wood flooring after 24 hours from its application at +23°C 50% R.H. Spread it with a smooth trowel or levelling bar onto the previously prepared, clean and dimensionally stable substrate. Average yield ≈ 1.6 kg/m2 per mm of thickness developed.