Details:

Soudal T Rex Xtreme Adhesive Sealant

Product Description

Soudal T-Rex Xtreme Adhesive Sealant is a high strength adhesive with extreme tack for immediate bonding of extremely heavy materials without additional support. Due to its extreme tack, it is capable of carrying heavy loads up

to 400 kg/m². Perfect for installing heavy items without slipping.

It is based on the unique SMX® Hybrid Polymer technology developed by Soudal.

Properties

Soudal T Rex Extreme Adhesive Sealant properties are as follows:

• Extreme high initial tack of min. 400 kg/m²

• Fast curing

• Good workability with included triangular shaped nozzle.

• High shear strength after full cure (no primer)

• Stays elastic after curing and very durable

• No odour

• Good weather and UV resistance

• Free of isocyanates, solvents, halogens and acids

• Good adhesion to most common substrates, even on damp substrates

• Permanently elastic after curing

Applications

Soudal T Rex Extreme Adhesive Sealant can be used for:

• Bonding in the building, construction and metal industry.

• Elastic bonding of objects, panels, profiles and other pieces on the most common substrates (wood, MDF, chipboard, etc).

• For bonded facade panels we refer to the Soudal Panel System.

• Elastic structural bonding in automotive applications: buses, trains, trucks, caravans or trailers …

Packaging

Colour: white, black

Packaging: 290 ml cartridge

Shelf Life

15 months in unopened packaging in a cool and dry storage place with temperature between +5°C and +25°C.

Chemical Resistance

Good resistance to (salt)water, aliphatic solvents, hydrocarbons, ketones, esters, alcohols, diluted mineral acids and alkalis. Poor resistance to aromatic solvents, concentrated acids and chlorinated hydrocarbons.

Substrates

Substrates: all usual building substrates, brick, concrete, metals, treated timber, PVC, plastics…

Nature: rigid, clean, free of dust and grease, dry or slightly moist.

Surface preparation:

Soudal T Rex Xtreme Adhesive Sealant has a good adhesion to most substrates. However, for optimal adhesion and in critical applications, such as joints exposed to extreme weather conditions, high- or water- loaded joints, we recommend to follow a pretreatment procedure. Prepare non-porous surfaces with a Soudal Surface Activator or cleaner (see Technical Data Sheet). Porous surfaces should be primed with Soudal Primer 150.

Soudal T Rex Xtreme Adhesive Sealant has excellent adhesion on most substrates. Soudal T Rex Xtreme Adhesive Sealant has been tested on following metal surfaces: stainless steel, AlMgSi1, electro-galvanized steel, AlCuMg1, hot dip galvanized steel, AlMg3, steel ST1403. T-Rex X-Treme also has a good adhesion on plastics: polystyrene, PVC, polyamide, fiberglass reinforced epoxy, polyester.

While producing plastics very often releasing agents, processing aids and other protective agents (like protection foil) are used. These should be removed prior to bonding. For optimum adhesion the use of Surface Activator is recommended.

NOTICE: bonding plastics like PMMA (e.g. Plexi® glass), polycarbonate (e.g. Makrolon® or Lexan®) in stress loaded applications can give rise to stress cracking and crazing in these substrates. The use of T-Rex X-Treme is not recommended in these applications.

Not suitable for PE, PP, PTFE (eg. Teflon®), bituminous substrates, copper or copper-containing materials such as bronze and brass. We recommend a preliminary adhesion and compatibility test on every surface.

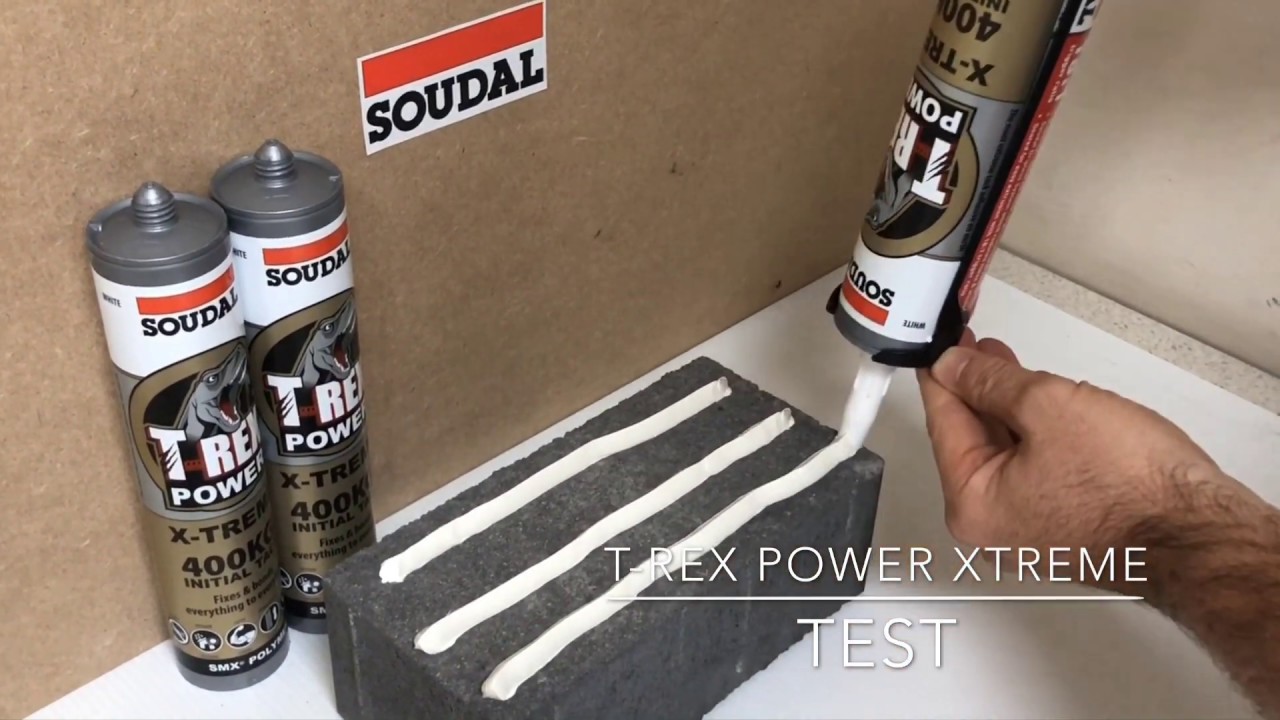

Application Method

Refer to the current Technical Data Sheet on our website prior to use.

Apply the product with high thrust-ratio caulking gun in uniform bead strips every 15 cm on one of the substrates. Always apply bead strip on the panel corners and edges. Do not apply in closed circumferences (non-porous surface). Bond the substrate and tamp with a rubber hammer. If necessary support the bonded materials.

The bond can be fully loaded after 24-48 hours.

For thicker adhesive layer and non-porous substrates, curing time is extended.

Application method: With manual- or pneumatic caulking gun.

Cleaning: Clean with Soudal Surface Cleaner or with Soudal Swipex, immediately after use.

Cured Soudal T Rex Xtreme Adhesive Sealant can only be removed mechanically.

Finishing: With a soapy solution or Soudal Finishing Solution before skinning.

Repair: With the same material.

Health and Safety Recommendations

Take the usual labour hygiene into account. Consult label and material safety data sheet for more information. Use only in well-ventilated areas.

Remarks

• Soudal T Rex Xtreme Adhesive Sealant may be overpainted with water-based paints, however due to the large number of paints and varnishes available we strongly suggest a compatibility test before application.

• The drying time of alkyd resin-based paints may increase.

• Soudal T Rex Xtreme Adhesive Sealant can be used for bonding of natural stone, but it cannot be used as a joint sealant on this type of surface. Soudal T Rex Xtreme Adhesive Sealant can therefore only be used on the bottom of natural stone tiles.

• When applying, make sure that the surface of the materials is not smudged with sealant.

• A total absence of UV can cause a colour change of the sealant.

• When using different reactive joint sealants, the first joint sealant must be completely hardened before the next one is applied.

• Not suitable for bonding aquariums.

• Do not use in applications where continuous water immersion is possible.

• Discoloration due to chemicals, high temperatures, UV-radiation may occur. A change in colour does not affect the technical properties of the product.

• Contact with bitumen, tar or other plasticizer releasing materials such as EPDM, neoprene, butyl, etc. is to be avoided since it can give rise to discolouration and loss of adhesion.

Additional Information:

Categories: Construction Adhesives, Silicone, Sealant and Adhesive Products, Soudal

Tag: Soudal