Drills vs. Impact Drivers: How to choose the right drilling tool for the job.

Drills are a staple of any toolbox. Whether you’re a DIY-er or a tradie, you won’t get far without a drill. Most commonly used for driving in screws and drilling holes, a drill is a versatile tool that can do all sorts of things if you’ve got the right attachment.

Some jobs, however, will require an Impact Driver. Impact Drivers have been gaining popularity in recent years, and they look very similar to a traditional power drill. Yet they function a bit differently, and they have different uses.

We’ll discuss the differences between the two, as well as some other things you should consider when choosing the right drill for the job.

What’s the difference between a drill and an impact driver?

An impact driver harnesses more torque than a drill and can drive in screws with much more force. This is mostly due to a difference in the way they rotate: a drill simply rotates the chuck (those three little grippy bits) and the attached drill bit, and that’s all there is to it.

An impact drill will also spin the chuck, but it’s got an extra trick up its sleeve. When the screw you’re driving starts to get stuck and the chuck slows down, a small anvil inside the impact driver starts striking the chuck thousands of times a minute to drive the rotation.

These ‘impacts’ give the impact driver a lot of extra torque to drive the screw through tough materials, and it will save the user a lot of energy and frustration.

One other key difference between drills and impact drivers is the type of chuck: most impact drills use a quick lock ¼” hex chuck, and therefore only take ¼” hex drill bits. Your round drill bits won’t fit into your impact driver, making it a bit less versatile than a regular drill.

When you should be using an impact driver

Because of the extra torque it provides, there are quite a few situations where an impact driver is a much better choice than a drill.

Always use an impact driver when you need to drive a screw through metal or particularly dense, knotted wood. It’s also better for driving long screws and lag bolts, which can be hard work otherwise.

In particular, impact drivers are good for when you need to drive in a hell of a lot of screws, like if you’re building a DIY deck or working on a construction site. You’ll find that your wrists and hands get much less exhausted than they would using a drill, and you can work for a lot longer.

Another advantage of impact drivers is that they don’t strip screws as much as regular drills do. This is because the short pulses of anvil-driven torque tighten in a more controlled way than a regular drill, so there’s less slipping about and less wearing away of the screw head.

Unfortunately, there are still some materials – like concrete – that are still too tough for an impact driver. For these situations, consider a Hammer Drill, a close cousin of the impact driver. Instead of using an anvil to increase torque, a hammer drill drives the chuck forward in a rapid hammering motion.

When to stick to your trusty drill instead

Impact Drivers are amazing at what they do, but they’re not quite as versatile as a classic cordless drill.

When you’re dealing with a job that requires precision, you’re better off with a drill. Impact Drivers may have plenty of extra torque, but this means they’re not as accurate when it comes to delivering uniform hole size and precise placement.

The other advantage of a drill is versatility. There are many different drill bits available that perform all kinds of tasks that require rapid rotation. Because the impact driver is limited to ¼” hex shank bits, you have less flexibility in the different tasks you can complete

Other things to consider: Brush Motor or Brushless?

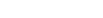

There’s one other thing you should really be considering when you’re thinking about buying a drill: is the motor brushed or brushless?

The difference between the two is friction. Brushed motor drills are a cheaper option, but they’re a bit less efficient and the friction produced by the brush means that certain parts may need to be replaced over time.

Brushless motor technology is a bit more advanced, and it doesn’t produce any friction when it operates. They have more efficient battery lives and they’re considerably more powerful overall. The total lack of friction inside the motor also means they need a lot less maintenance.

If you expect your tools will get a lot of heavy use, you should definitely invest in a brushless tool. If you think you’ll only use it occasionally, you can save money by getting a brushed tool instead. This is why it’s important to think about this when you’re considering buying a drill or an impact driver.

It’s always important to choose the right tool for the job. Hopefully, this blog has helped you understand a bit more about the difference between impact drivers and drills, and made it easier for you to make the right choice.

Shopping for a drill or an impact driver? At Multifors, we stock a huge online range of power tools and power tool accessories, delivered anywhere in Metro Melbourne for only $19.95. Make it easy to get started on the job right away.

-

11, Jul, 2022

11, Jul, 2022Feature Product: The Stain Proof Range

We regularly review some of our favourite products. Today, we’re... -

5, Jul, 2022

5, Jul, 2022Concrete Sealer: What You Need to Know

Concrete is a sturdy material that’s practical and affordable. In... -

24, Jun, 2022

24, Jun, 2022A Product Guide for DIY Pool Areas

Tiling a pool area is a great DIY project. In...